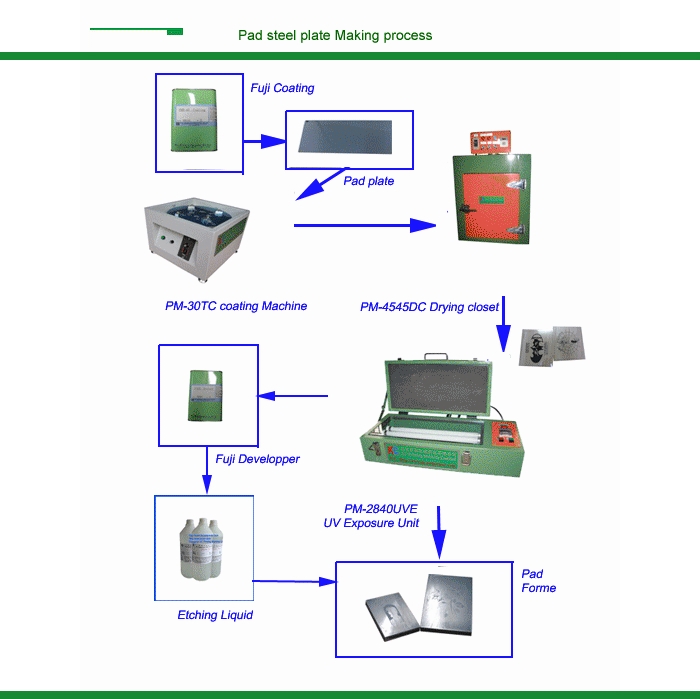

Pad printing machines, like other printing machines, use printing plates. At present, pad printing resin plates and steel plates are used more frequently. Pad printing resin plates are made by special resin plate making machines, and steel plates are mainly made by corrosion methods. It is reported that some laser marking machines can directly engrave steel plates, but the response in the market is not very mature. If the technology of laser engraving machines is mature in making steel plates, it will be the dawn of pad printing steel plates to get rid of complicated and environmentally friendly processes.

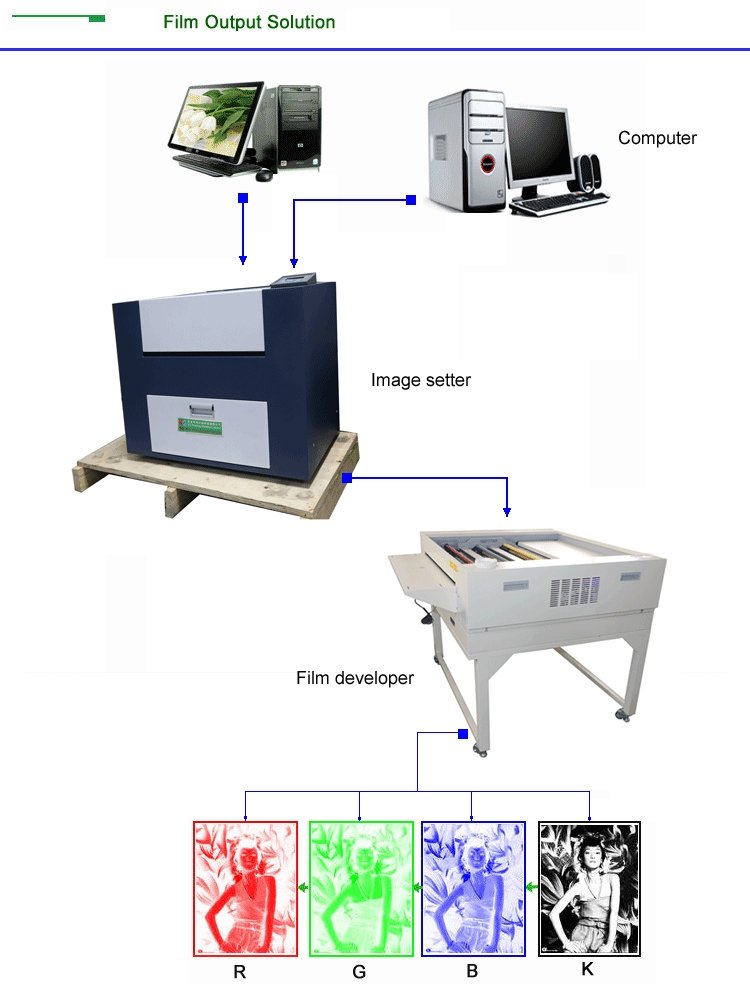

The corrosion method of pad printing steel plate currently occupies a dominant position in the market. It has two important steps. One is to use a laser phototypesetting machine to make the film, and the second is to use the film to bond the steel plate for printing, and then use the corrosion method to make the film. Pad printing gravure, you can find related files on youtube video website or some professional websites.

Brefie |

|

Usage |

|

Package |

|

Store |

|

Parameter |

|

Advantage |

|

Usage |

|

Reminding |

|

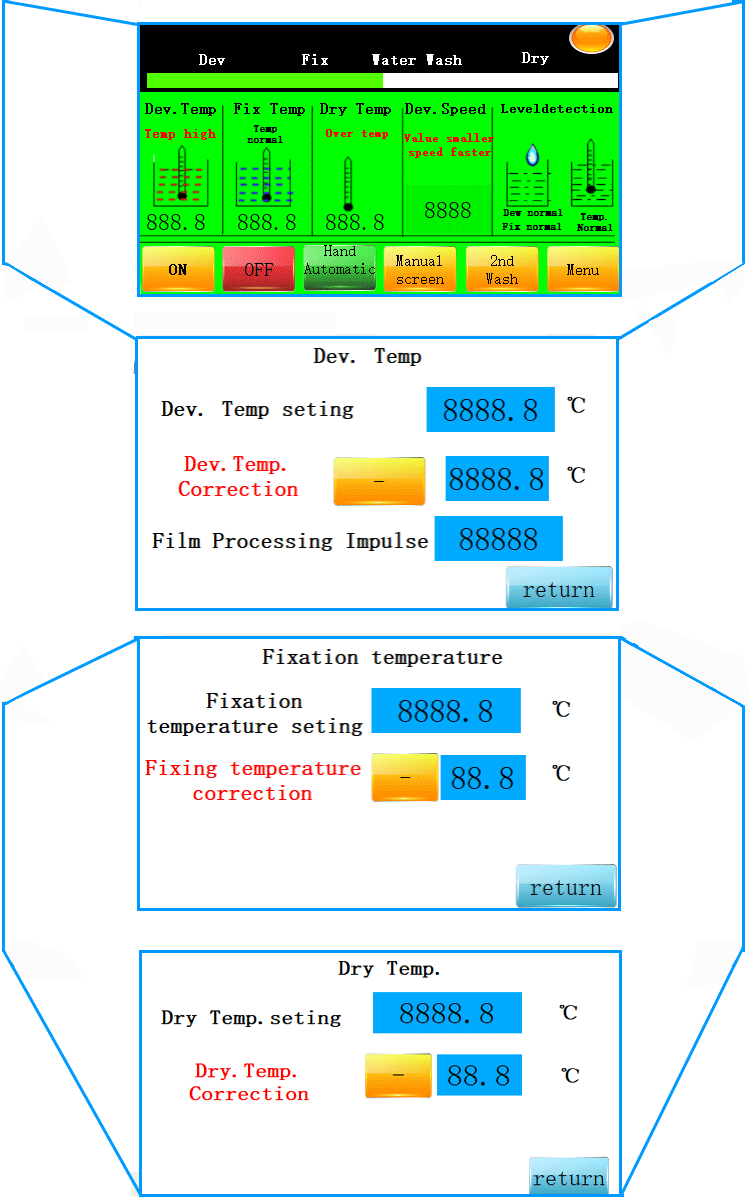

Development principle:

After exposure, the film enters the developer of the film processor, and the chemical components in the developer react chemically with the exposed photosensitive material on the film. The photosensitive material in this area is converted into a visible black or other color image material, and the image gradually appears. In the unexposed area, the photosensitive material reacts very slowly or almost not at all with the developer. The photosensitive material in these areas remains basically the same and will be removed or retained as a blank part in the subsequent processing process, thus forming a developed image corresponding to the exposure pattern. After development, the film enters the fixer, and the unreacted photosensitive material on the film fixes the image that has been formed. The chemical components in the fixer can react with the unreacted photosensitive material, dissolve it and wash it off the film, leaving only the stable image that has been developed. After the fixation process, the image on the film will no longer be affected by subsequent chemical treatments or external factors. After the fixation is completed, the film needs to be dried to remove the residual developer and fixer on the film. Water such as dry film is dried for subsequent use and storage.

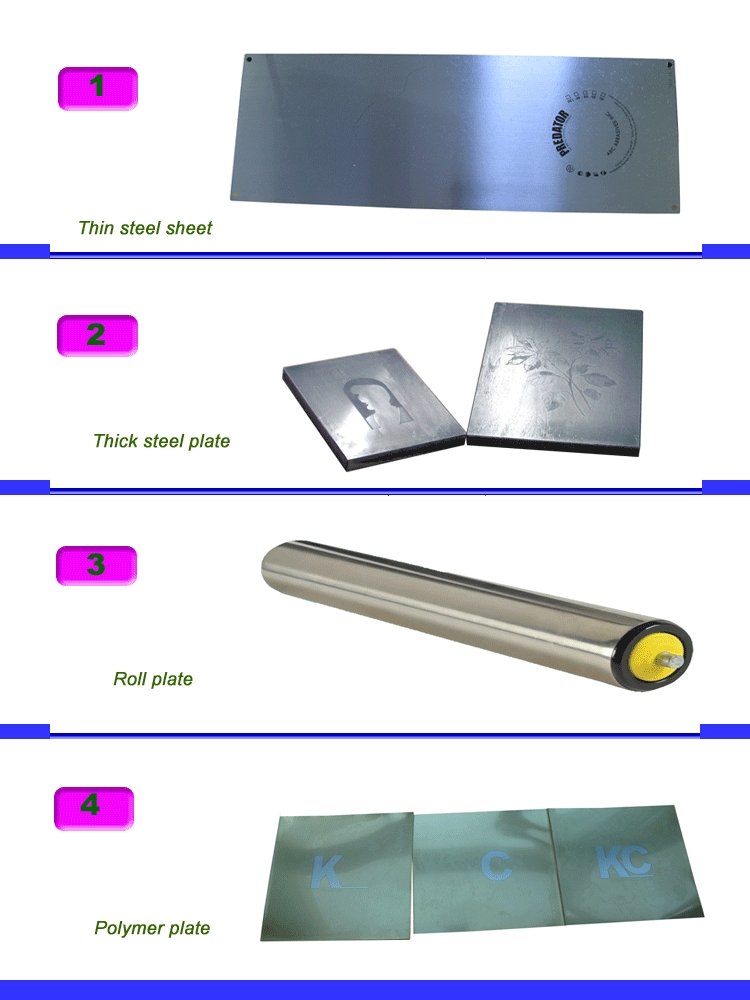

There are three kinds of pad plate: thick steel plate, thin steel plate, nylon resin plate. Making the pad plate is the first step to begin pad printing technology.

Film after the formation of latent image after exposure to water after developing and fixing of water freeze treatment. Ultimately form the image area and non-image area.

In the modern printing industry, copy of film making is all the printing program when one of the first, it is directly related to the printing quality. Therefore, gravure printing, offset printing, letterpress printing all of this as an important part of pre-press technology to treat.

Although the CTP technology are advancing rapidly, but in the plate-making technology, especially printing, silk screen, hot stamping field, still holds an important position.

Usage︰

Using PM-310FL film output machine film exposed film developing and fixing processing.

Photographic film output has been, you need water to develop water and fixing latent image freeze, the formation of the final film for the printing down the process of printing down.

Production Advantage ︰

Powder Package, easily for keeping;

Use Method︰

the developer of the preparation

Developer can prepare them by themselves can also buy ready-made packaging development powder. Developing powder is extremely easy to use package, usage is simple, become suitable for a small amount of flushing Gan Guangpian or print and images.

1) Prepare the developer of the water temperature is best maintained at 52 ℃. Temperature is too low, slow dissolving drugs, the temperature is too high, easy to make medicines chemical changes affect performance.

2) The developer of water must be clean, not to use water impurities. Contain too much iron, magnesium, aluminum, calcium in hard water should be boiled to soften; by polluted water, add alum to precipitate filtered.

3) The developer developing drugs affect the performance of dosage, so the dosage must be in accordance with the formula provided, it should not change.

4) deployment of liquid should be stirred properly to promote the dissolution of chemicals. Stirring time should not be too keen to avoid too much air dissolved in water, to promote oxidation not keep liquid.

5) The deployment of a good developer, and often there are a number of impurities, apply a clean gauze or filter paper, photographic material generated class to avoid points.

6) "Snapshot: that is to restore the silver film on the silver does not dissolve in order to prevent further exposure of this part of silver halide film image. Fixing time for hand-punching is no photographic film after partially transparent, plus double the time.

7) "washing: Fixing sticky film after the sodium thiosulfate and other chemicals, if not clean, the film will turn yellow failure. Hand punching usually running water 15 to 20 minutes is appropriate.

8)"dry: hand after punching the film should be dried and placed in a cool dry place for safekeeping.

Storage︰

Developer and fixation easy long-term exposure to air oxidation, should be installed in the brown bottle Gaiyan, placed in the shade, avoid sun exposure

Pad plate styles

Water-washed pad printing plates and alcohol-washed pad printing plates have independent and obvious advantages. Resin plates are widely used in countries and companies that pay attention to environmental protection, because the entire plate-making process is harmless, and it is used for developing after exposure. Both water and alcohol can be discharged directly into the water circulation system without worrying about polluting the water body. The resin used in the resin version itself is also easy to degrade and will not produce chemically toxic components.

The thin steel sheet is subjected to surface quenching treatment, and the hardness can reach 60 degrees. The thickness is between 0.3-0.5mm. Common fabrication methods include ferric chloride etching and laser engraving. The iron trichloride corrosion method has been used to make steel plates, but it is basically banned in developed countries, and the laser engraving method is a technology worth promoting. It does not require film sheets and is very environmentally friendly.

Both thick steel and roller pad printing plates are used for high-volume printing tasks.

Those high-end users should understand that the excellent flatness and smoothness of the steel plate ground by a high-precision grinding machine will definitely bring superior performance to your printing tasks.

Of course, the obvious disadvantage of thick steel and roller plates is that they are difficult to replace because they are heavy and not easy to move.