How to make screen plate

1. Screen degreasing

All the screen, whether it is new or used stencil should be degreased. This is to produce high-quality halftone indispensable step. In addition to the synthetic mesh, it must also play rough, to enhance the network version of the resistance to mechanical abrasion.

2. The photosensitive paste sensitized

Direct sensitive adhesive is usually equipped with a diazo sensitizer or sensitizers behalf of pulp. That is, before using a photosensitive paste, evenly mixed sensitizer to photosensitive paste in order to activate sensitized photosensitive paste.

3. Coating

Both manual and automatic coating machine can complete this process. The so-called squeegee is to use photosensitive paste layer sealed to the screen, but also the thread tightly sealed. Squeegee should be done in a slow, strong and uniform. Factors affecting the network version of the production effects are: screen mesh count, thread diameter, screen colors, screen tension and clean is clean, the thickness of the photosensitive paste curing degree and temperature, sizing knife, and scrape the pulp angle, speed and so on.

Squeegee There are three ways:

1) First printing surface layer of screen scraping, and then in the network version of the plastic surface scratch on the floor. Final drying. From the printing results, the photosensitive layer on the thin scraping, screen thickness small halftone ink storage capacity will be less.

2) In the first screen printing surface scratch or two, and then squeegee the surface scratch 1-5 down, every scratch it, turn 180 degrees Mobility version, then flat, dry, print side down. Such produce halftone and ink slightly larger reserves.

3) On the basis of the second method, that is, after drying, then a layer, and then dried in the Web version of the printed surface scratch, so produced halftone thicker, larger reserves ink, the printing pattern trimming tension high.

4. Drying

In order to improve the clarity of pattern and paste in the photosensitive ensure uniform distribution of the screen surface, the drying process should ensure that no dust pollution around, and should be operated in a dark room or yellow light. When placed in the frame, print side down, to keep the screen horizontally. Although in the case of a dust-free drying fan is available, but in order to speed up the drying speed, drying box can be used (Note: The maximum temperature should not exceed 40 ℃).

Since the wet surface will affect photosensitive paste sensitive to light, it must be done thoroughly dried scratch coating layer before exposure. Without completely dry conditions, there will be underexposed.

Drying Instructions:

When using a third method of scratching, each painted a must do on a fully dried coating, otherwise moisture will sandwiched between the photosensitive layer.

If possible, keep the indoor temperature constant. If the indoor humidity, to extend the exposure time, especially in the summer, if not lower humidity means, should pay special attention to this point. In fact, the cost of installation means lower humidity is not too high.

Often using the dryer (maximum temperature of 40 ℃) in the industry, especially in the more humid environment. But you must know, since the heating network will block the expansion of chromatic inconvenience that it is difficult to achieve accurate color. Therefore, to ensure accurate color, all screen and screen frame to be dried in the same environment. And prior to exposure, they should be allowed to return to room temperature.

The operating environment, we should try the exposure, dry place with the screen frame production, cleaning the place apart, as in the production of wire mesh and wash areas more humid.

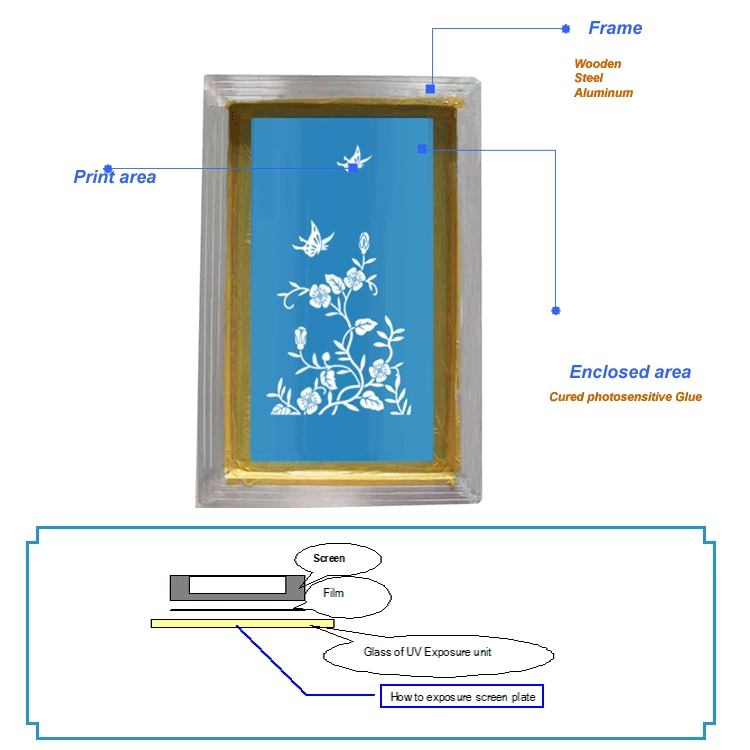

5. UV Exposure

Exposure operation belong to one of several important steps to master good or bad related to exposure pattern fineness, pattern edge sharpness and wear resistance pattern. In order to ensure good exposure effect, perform the following three steps: a rough calculation of the exposure time, the exposure test trials were distributed and were compared with a screen printed pattern and negatives.

Rough calculation of the exposure time

There are many factors that determine the length of time of exposure, according to the actual situation, calculate the printing method suited to their own environment and exposure time.

View basic exposure schedule, mainly to see the light source and the photosensitive paste scratch coating method used.

It lists the factors that influence the exposure (such as dyeing mesh, humidity, etc.) each factor has an impact factor (commonly known as "exposure factor"). For example, if you use multifilament polyester mesh, the exposure factor of 1.3-1.5.

The exposure time base multiplied by the exposure factor, draw a rough exposure time.

Exposure time base X = rough exposure time exposure factor

Screen preparation exposure guidelines:

Metal wire cloth and wire mesh shading dye is strong, therefore, the required exposure time is longer. Coarse mesh fine screen exposure time is longer than desired.

In order to ensure clarity of the halftone pattern and jagged teeth and bite phenomenon, let screen is in a good vacuum, in order to ensure full contact with the photosensitive layer backsheet, and should be remembered for the exposure time to stain the screen correspondingly longer.

Using tunable light source (finger position is adjustable), in order to ensure a uniform screen exposure and reduce tooth biting phenomenon, the best distance is 1.5 times the diagonal pattern of the sun or 1.5 degrees screen diagonal length.

Underexposed, often brings the halftone can not be reused or with trachoma and serrated. When rinsing, if the network version of the squeegee surface sticky and soft feel, indicating that the screen is underexposed, that there is not enough light reaches the squeegee side of the photosensitive layer so that the photosensitive layer can easily be washed away. Meanwhile, the lack of exposure, the photosensitive layer of the photosensitive layer even softer easily be washed away. So that the screen is not resistant to mechanical abrasion and solvent resistance is poor.

Sometimes, there are some underexposed stencil can be taken remedial measures. The methods are: Gently rinse off screen, the photosensitive layer of softer wash, wipe with a white paper and then drying the screen, the last exposure.

Note that you must let squeegee facing toward the light source.

6.washing

After exposure, the screen is washed with a screen washing machine, and the screen will show an open image area and a closed non-image area. The finished screen can be installed on the screen printing machine for use.