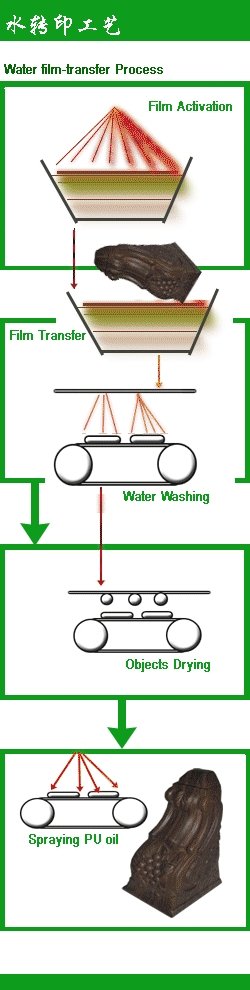

major hardware facilities to complete the water transfer process

Film Feeding equipment

Film feeding equipment mainly to the completion of the water draped whisk transfer film graphic activation and transfer of film to the surface of the product. Feeding equipment is actually a thermostatically controlled water tank, some with white metal welded, some made of stainless steel

Automatic on membrane equipment used for the feeding film of the standard product operation. The robot can freely handling products, greatly improving the productivity, but also reduce the tedious manual procedures

Water transfer film good cut flat on the water surface of the membrane devices, the film after water absorption and water formed parallel to the storage state, the free floating on water, because the surface tension of water, the ink layer will be a uniform, flat Shop in the water. Activator uniformly sprayed on the surface of the film, the film will gradually destroyed and dissolved, the rendered free state due to the water resistance of the ink, the ink layer

Washing equipment

Washing equipment to complete the cleaning of the product surface residual film, the general washing equipment manufacturers into the pipeline in the form to facilitate continuous production. After the transfer of the product placed on the conveyor belt of the washing equipment (s), the operatives using manual methods of product residues cleaned and then exile in the next step

The main form of the washing equipment is provided above the conveyor belt of a different number of nozzles. Nozzle can spray pressure at the different sleep line, the waterline can wash away residual film of the surface of the product.

Drying equipment

Drying apparatus is used after removal of the residual film, after the operation of the products injection sulfate. For drying after washing is the evaporation of water, the injector after drying is the volatility of the solvent and dried. After the water evaporates, the graphic will form a close combination of force and product, and will form a high-gloss varnish dry, dense and hard graphic protection layer

There are two forms: drying equipment production lines and single Case, single case commonly used in products proofing process of drying, the pipeline drying equipment used for large-scale production. Pipeline drying equipment delivery device, drying apparatus, the main requirement is that the general design of the products to the terminal to be transported into the drying unit to dry thoroughly. Drying device by way of infrared heating

With the UV spray the rapid development of technology, the surface of the product UV spray began to receive attention, the UV environmental advantages and superior physical and chemical properties has been of concern for the field of water transfer. Dry UV spray technology is the use of UV drying production line, the UV drying production line and the traditional UV curing technology with UV curing machine and no difference

Spraying equipment

Spraying equipment is used for spraying the surface of the product after the transfer, it has the body and the fuel injection pressure means constituting the spraying with paint into fine particulate matter floating in the high pressure, when the product formed after adsorption force. Automatic injector device not only can automated operation of the product, also addresses the operation of employee health damage

Despite the water transfer process itself is little risk, but some of the water transfer process chemicals on the human body is water transfer equipment is not high degree of automation injury still relatively large proportion of the manual, these are water transfer some of the problems currently faced by the printing equipment. These issues will continue to be improved.