Hot stamping foil

Hot stamping film, also known as electroplated aluminum, is a hot stamping material made by coating and vacuum evaporating a layer of metal foil on a polyester film base. It is usually a multi-layer structure:

1. Base film layer: Generally, a 16μm thick biaxially stretched polyester film is used, which has high strength, tensile strength, high temperature resistance and other properties. Its main function is to support the coating attached to it, facilitate continuous action during hot stamping processing, and is not easy to deform due to temperature rise during hot stamping.

2. Release layer: Mainly coated with silicone resin and the like. During hot stamping, whether it is heated or pressurized, it can quickly separate the color layer, aluminum-plated layer and adhesive layer from the film and be transferred and bonded to the surface of the hot stamped object. The release layer must have good release performance, otherwise it will affect the quality of the hot stamped product.

3. Color layer: The main components are synthetic resins and dyes with suitable film-forming properties, heat resistance and transparency. It has two main functions, one is to display color, and the other is to protect the aluminum-plated layer images and texts printed on the surface of the object from oxidation. The color of the color layer is rich and varied, such as orange, yellow, gray, red, green, etc., and the color will change after the aluminum layer, such as yellow after aluminum plating to gold, colorless aluminum plating to silver, etc.

4. Aluminum layer: The film of the colored layer is placed in the vacuum chamber of the continuous aluminum plating machine. Under a certain vacuum degree, the aluminum wire is melted and continuously evaporated to the color layer of the film through resistance heating. The main function is to reflect light, change the color properties of the color layer, and make it glossy.

5. Adhesive layer: Generally, fusible thermoplastic resin is applied on the aluminum layer through a coating machine and dried. Its main function is to bond the hot stamping material to the object to be stamped.

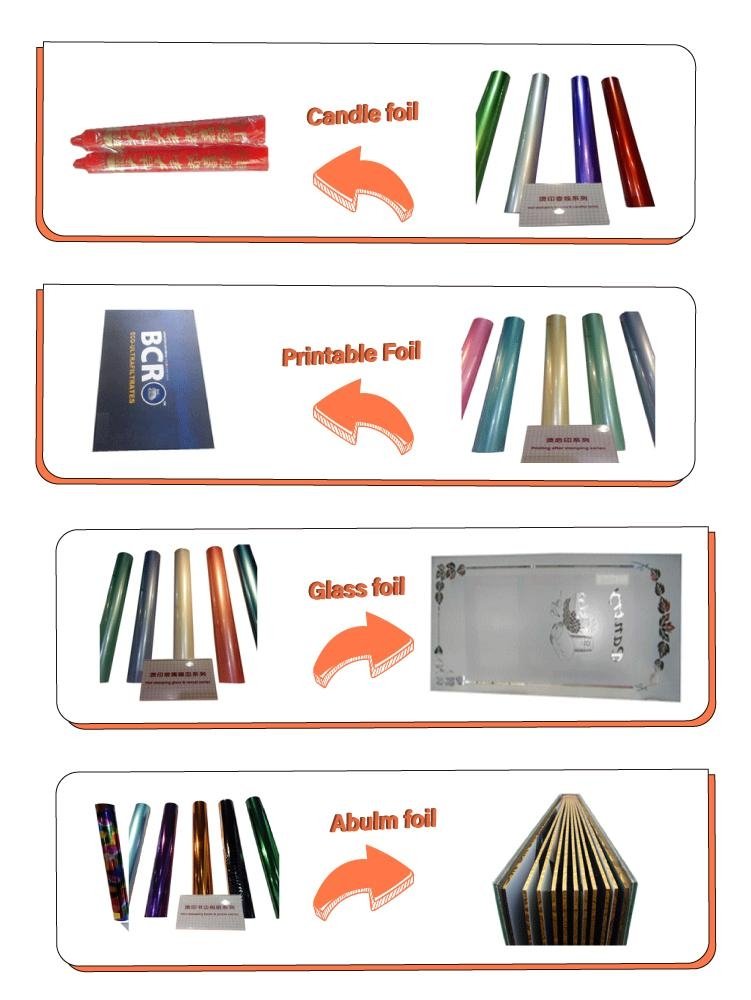

The hot stamping film is combined with a manual hot stamping machine, a pneumatic hot stamping machine, a hydraulic hot stamping machine and a fully automatic hot stamping machine to add a unique metallic luster and decorative effect to the surface of the product, and enhance the grade and beauty of the product. It is an important raw material for paper decoration, plastic packaging, cosmetics industry, artificial leather/textile industry, 3C products & home appliances, credit cards, book binding industry and other industries.

Used for various paper product packaging, such as paper boxes, gift boxes, packaging boxes, etc. Exquisite patterns and texts printed on gift boxes can enhance the packaging grade and attract consumers' attention.

Used for hot stamping of various fabrics, including clothing, home textiles, curtains, etc. For example, hot stamping on wedding dresses can add a sense of luxury, and hot stamping on home textile products can play a good decorative role. Hot stamping film for fabrics generally requires a layer of hot stamping paste to be silk-screened on the fabric first.

Mainly used for plastic products, such as plastic toys, plastic stationery, electronic product shells, etc. It can firmly adhere to the plastic surface, making the product look more exquisite. For different types of plastics (such as PVC, PP, ABS, etc.), there are different plastic hot stamping films to match them to ensure a good hot stamping effect.

Used for hot stamping of leather products, such as leather shoes, leather bags, leather clothes, etc. Hot stamping on leather can highlight the brand logo or increase the decorativeness of the product. The leather hot stamping film needs to consider the texture and surface characteristics of the leather to ensure the integrity and firmness of the hot stamping pattern.

Some glass and metal products also need hot stamping. The two materials cannot be hot stamped directly. You can first screen print glass varnish and metal varnish and then hot stamp. The choice of hot stamping film is related to the properties of the varnish used.

Thermal transfer film is a medium material for thermal transfer process, used in thermal transfer machine:

1. Structural composition:

• Base film layer: usually made of PET film, with high strength, high temperature resistance, good dimensional stability and other characteristics, providing a basic support structure for the thermal transfer film, and can maintain the shape and performance of the film stable during printing and transfer.

• Release layer: The main component is release agent, which is used to smoothly separate the other layers printed with patterns from the base film layer during thermal transfer, ensuring that the pattern can be completely transferred to the surface of the substrate, and there will be no residue after transfer.

• Ink layer: Attached to the release layer by printing, it contains adhesive resin, colorant and other ingredients. It is the key layer for presenting decorative patterns and colors, and can show a variety of exquisite patterns and rich colors.

• Protective layer: It can protect the ink layer from scratches and wear, prevent the pattern from being damaged during use, and also has certain waterproof and UV protection functions, which can keep the pattern bright and clear for a long time.

• Adhesive layer: generally composed of materials such as hot melt adhesive. During the thermal transfer process, the hot melt adhesive is melted by heating, thereby firmly bonding the ink layer and other layers to the surface of the substrate, ensuring that the pattern can be firmly attached to the substrate.

2. Production process:

Thermal transfer film is mainly printed by gravure printing machine, and its general process is as follows:

• Coating release layer: the base film passes through a coating device filled with a release agent solution, and a release layer is coated on the base film.

• Coating protective layer: a protective layer is coated on the release layer to enhance the wear resistance, light resistance and other properties of the thermal transfer film.

• Printing ink layer: after passing through the printing device, the required pattern and color are printed on the protective layer.

• Coating adhesive layer: finally, an adhesive layer is coated on the ink layer to make a thermal transfer film and roll it up.

The adhesive layer determines the properties of the thermal transfer film. Different materials require different adhesive layers. Customized thermal transfer films should provide product material information and conduct necessary tests.

3. Advantages:

• Exquisite patterns: It can print various complex, fine and colorful patterns, and the transferred patterns have high clarity, strong layering and good visual effects.

• Wide application: It is suitable for surface decoration of various materials, such as plastics, metals, ceramics, wood, glass, etc.

• High production efficiency: The thermal transfer process is relatively simple to operate, and the pattern can be quickly transferred to the substrate, which is suitable for large-scale production.

• Good environmental protection: Compared with some traditional printing methods, thermal transfer films produce fewer pollutants during production and use, and have less impact on the environment.

• Good durability: The transferred pattern has excellent properties such as wear resistance, heat resistance and light resistance, and can maintain stability for a long time.

Description

It is very difficult to print Halftone drawing or muti-clour on plastics products with screen printer . but it is easy by photopravure press.

1) First printed with photopravure press on PET film;

2) Transfer with Heat transfer machine or hot stamping machine;

3) Some heat transfer film printed by screen printer, this film is more coarse.

Usage︰

Suitable for Muti-colour decoprating on Palstics, wooden surface.

Operation panel; Varnish barrel, Plaything,

Writing pen, Plastics bottle.

Technical Parameter︰

Base: PET film;

Thickness of film: 35um-75um

Production Advantage ︰

Suitable for most of plastics: ABS, PC, PS, PMMA, PP PE;

Suitable for wooden products;

Suitable for Glass products;

Suitable for metal surface covered with varnish.

Use Method︰

Used by hot stamping machine or heat transfer machine.Printing Plate type︰ Printed by Photopravure press installed engraving plate or Corroded plate.

Suitable for objects made by PE materials

Suitable for objects made by PE materials

Suitable for other plastics products

There are many original sizes of hot stamping paper, most of which are rolls with a width of 64cm and a length of 120M. Users can cut the hot stamping paper into different widths according to the size of the hot stamping pattern. The hot stamping paper can be cut with an electric hot stamping paper cutting machine or a manual cutting machine.