Plastic baskets are commonly used in supermarkets, restaurants, internal material transfers in factories, and large-scale liquid filling factories: such as beer, beverages and other products, storage, operation, loading and unloading are inseparable from plastic baskets. Some plastic baskets often use bronzing process for simple decoration.

Plastic baskets often have a huge space. In order to improve the strength, the four walls of the plastic basket are equipped with stiffeners of different heights, so that the surface of the plastic basket is uneven.

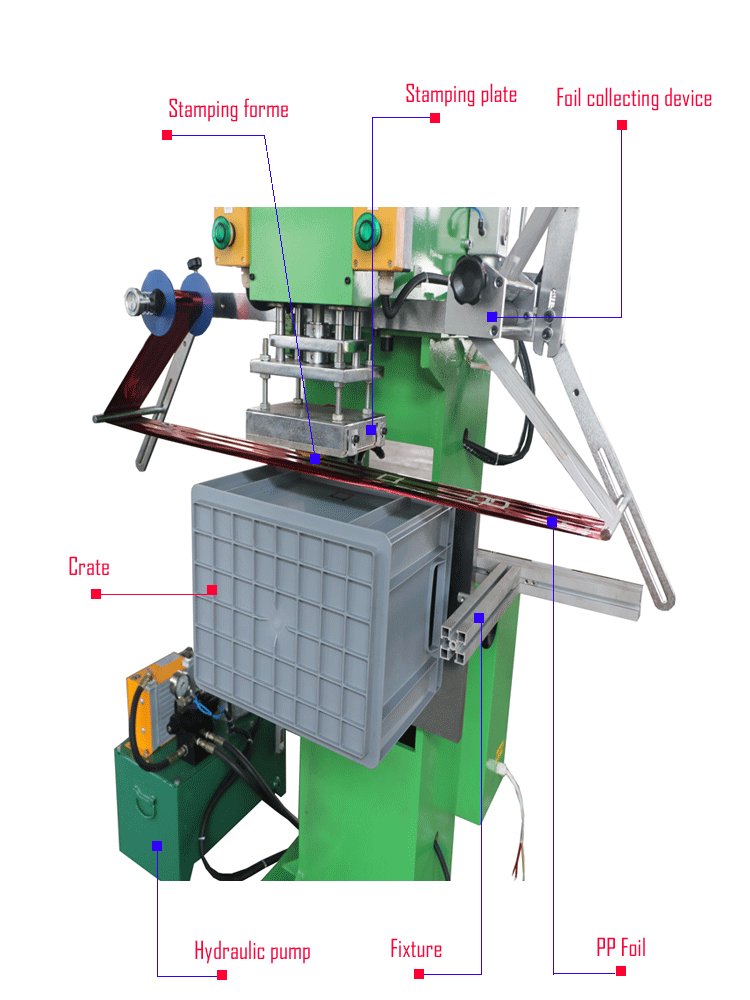

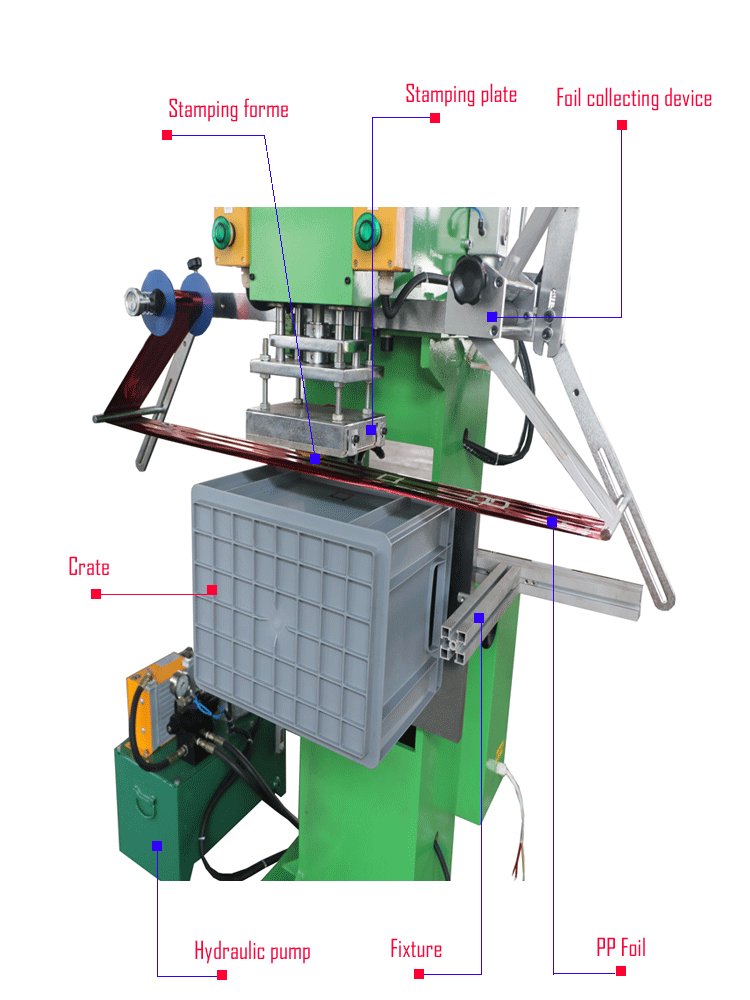

In order to achieve hot stamping on the surface of the plastic basket, necessary changes must be made on the hot stamping machine. These changes include:

Install the cantilever workbench, install the higher hot stamping plate, the hot head can be adjusted up and down, left and right, front and rear directions, and the frame can be positioned in multiple directions.

Most of the plastic baskets are made of hard PP and PE materials, which require a lot of hot stamping pressure to achieve. Therefore, hydraulic hot stamping machines are given priority, and it is also possible to use high-pressure pneumatic hot stamping machines. It should be pointed out that the pressure is a very important factor for the hot stamping of hard plastics, especially plastic baskets. If the pressure is not enough, it is almost impossible to achieve beautiful hot stamping.