Model No.︰HM-TC3030LT

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 1350 / pic

Minimum Order︰1 pic

The semi-automatic hot stamping machine is mainly composed of the up and down of the hot stamping head, the conveying of the hot stamping paper, etc. We mainly name the hot stamping machine based on the control method of the hot stamping head up and down. Manual hot stamping machines are the simplest type of hot stamping machine. The conveyance of the hot stamping paper and the heating of the heating plate of the manual hot stamping machine still need electricity. The manual hot stamping machine is widely used in hot stamping processing in stores and small-scale factories, and can hot stamp most products such as paper, leather, plastic, and wood.

|

Manual hot stamping Machine //Structure |

||

|

Working table |

Manual in-out , size: 420*500mm. |

|

|

Stamping Head drive |

Manual , Level keeping pressure |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press |

Vertical press |

|

|

Temperature control |

Heater tube, automatically controlling |

|

|

Foil collecting |

Automatically collecting |

|

|

Press adjustment way |

Up-down of working table |

|

|

Manual hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Manual hot stamping Machine //Parameter |

||

|

Technical parameters |

HM-TC3030LT |

HM-TC3035LT |

|

|

|

| HM-TC3040LT | HM-TC3045LT | |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Manual hot stamping machine //Advantage |

||

|

Function |

|

|

Basic Configuration︰

1. Silicon rubber Edition one pic;

2. High temperature Paper one inch;

3. Stamping foil one roller;

4. One set tool;

5. Spring 2 Pcs;

6. AC contactor 1 pc;

7. Rubber Ring 1 pc;

8. Thermocouple 1 pc;

9. Limit Switch 1 pc;

10. Heater tube 2 pcs.

Base structure︰

Body

The body is the basic frame of the entire manual hot stamping machine, which is used to support and fix other parts to ensure the stability of the machine. It is usually made of metal materials, such as cast iron or steel, to give it sufficient weight and strength to reduce shaking during the hot stamping operation.

Heating plate and temperature control system

The heating plate is a key component of the hot stamping machine, and a heating element, such as an electric heating tube, is installed inside. It can quickly heat up and remain within the set hot stamping temperature range to provide heat for hot stamping. The heating and constant temperature control of the heating plate are controlled by the thermostat, and the operator can set different temperatures according to the different hot stamping materials.

Pressure regulating device

The pressure is adjusted by a handle, a screw or a pneumatic device. For example, when using a screw structure, the screw is moved up and down by rotating the handle, thereby changing the distance between the heating plate and the workbench, thereby adjusting the pressure during hot stamping.

Workbench

The workbench is where the hot stamping material is placed, which can withstand a certain pressure and temperature while avoiding scratching the hot stamping material. To prevent the product from moving during the hot stamping process, the workbench may be equipped with some simple positioning devices, such as clips or magnetic devices. Clips can clamp the edges of materials such as paper and leather, while magnetic devices are suitable for some metal materials that can be magnetically attracted. Some products require special fixtures to fix the product.

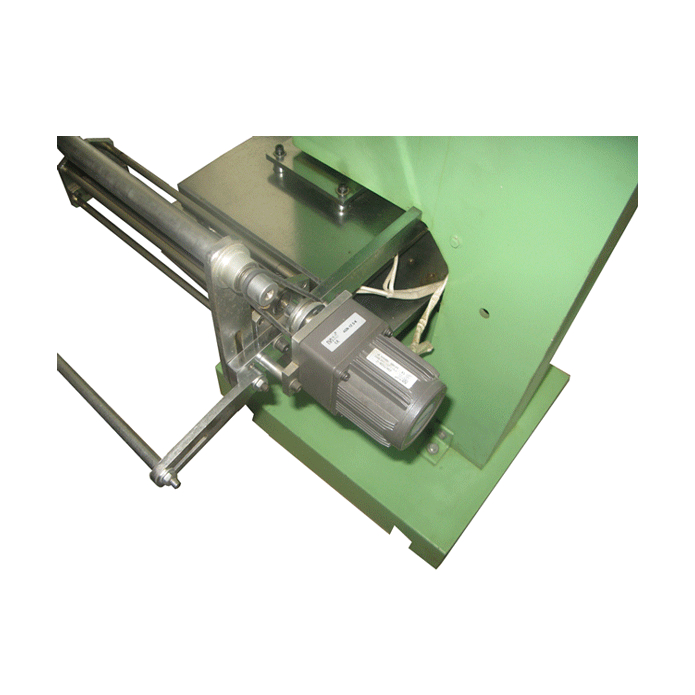

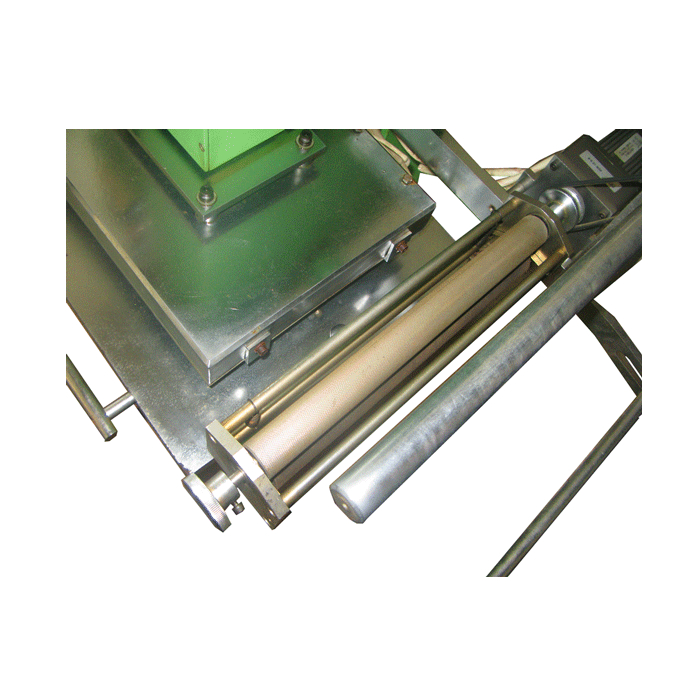

Hot stamping foil conveying device

Includes unwinding structure and rewinding mechanism: used to place hot stamping foil rolls and collect used hot stamping foil. Hot stamping foil conveying device is generally controlled by micro motor.