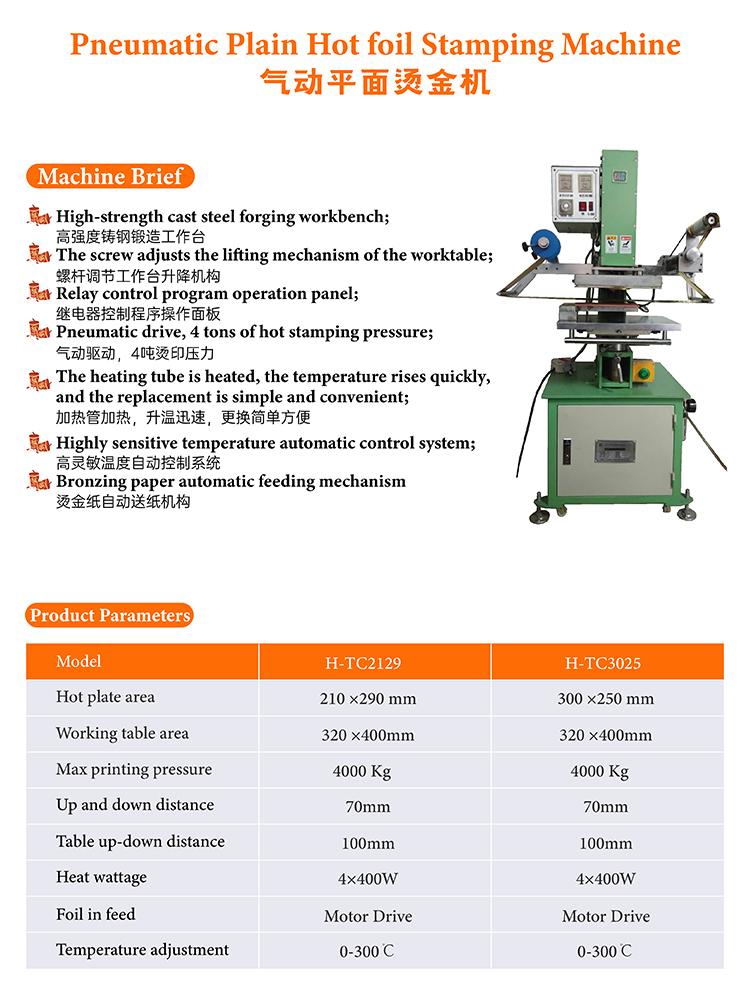

Model No.︰H-TC3025

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 2441 / pic

Minimum Order︰1 pic

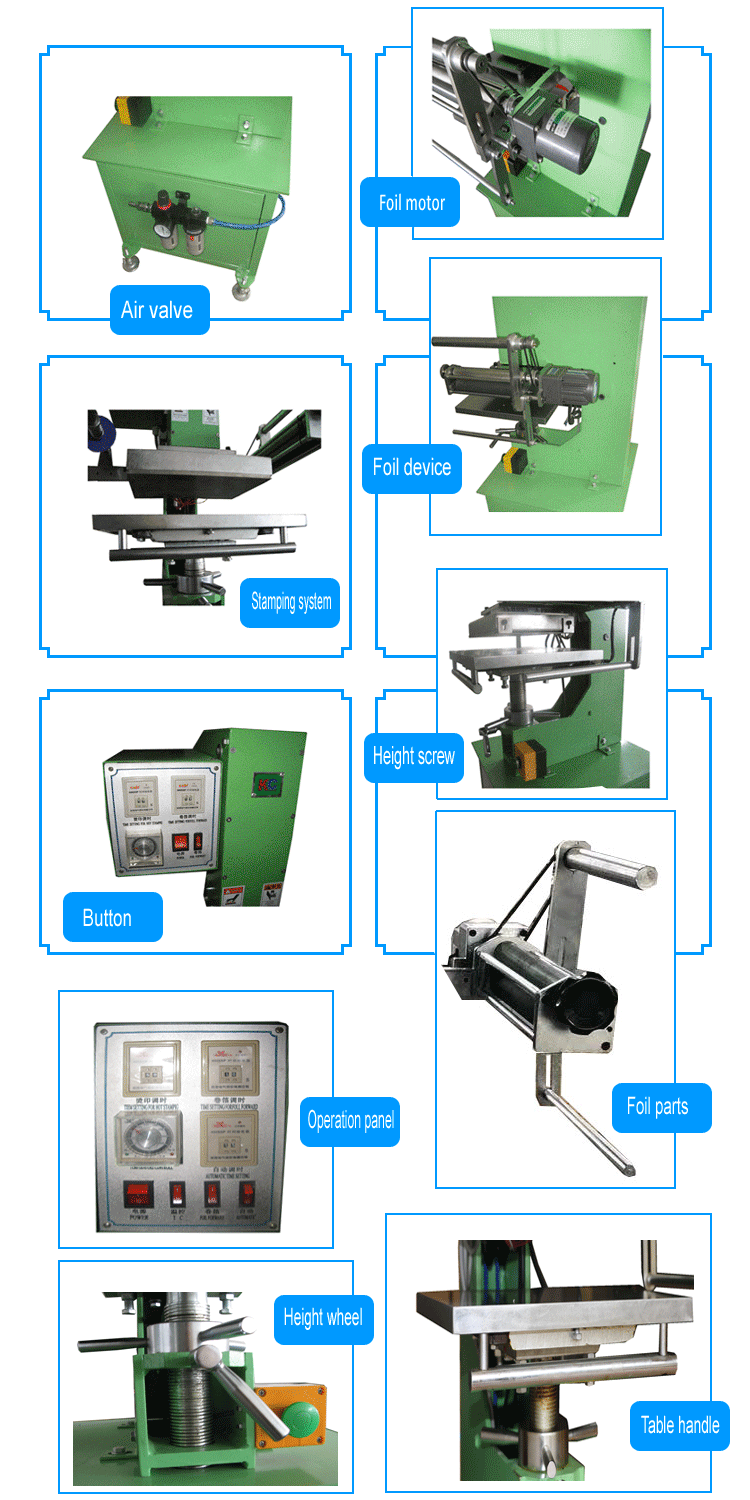

Structure

The pneumatic hot stamping machine is mainly composed of the fuselage, pneumatic system, heating system, hot stamping plate and workbench. The fuselage is the frame of the whole machine, providing support and stability. The pneumatic system includes cylinders, air pipes and pneumatic valves, which are components that provide pressure. The heating system is usually composed of a heating plate and a temperature control device, which is responsible for heating the hot stamping plate to a suitable temperature. The hot stamping plate is installed on the heating plate to carry the hot stamping pattern or text, and the workbench is used to place the items that need hot stamping.

Principle

The pneumatic hot stamping machine uses compressed air to drive the cylinder so that the hot stamping plate fits tightly with the object placed on the workbench. At the same time, the heating system heats the hot stamping plate, and the hot stamping foil on the hot stamping plate transfers the pattern or text to the surface of the object under the action of high temperature and pressure. Its principle is based on hot pressure transfer, that is, the glue layer of the hot stamping foil is melted by heat, and then it is firmly bonded to the surface of the object with the help of pressure.

Operation process

1. Preparation: Connect the power supply and air source, install the hot stamping plate and hot stamping foil, and place the items to be hot stamped on the workbench.

2. Parameter setting: Set appropriate parameters such as temperature, pressure and hot stamping time according to the characteristics of the hot stamping material and object.

3. Test operation: Perform hot stamping tests on a small number of samples to check whether the hot stamping effect meets the requirements. If there is any problem, adjust the parameters in time.

4. Formal hot stamping: Place the items to be hot stamped on the workbench in turn and start the machine for hot stamping operation.

5. Complete hot stamping: After the operation is completed, turn off the power supply and air source, and clean the machine and work area.

Scope of application

Pneumatic hot stamping machines are widely used in packaging, leather, plastics, paper and other industries. For example, in the packaging industry, gift boxes, cartons, etc. can be hot-stamped to increase the beauty of the products; in the leather industry, it can be used for hot-stamping of leather shoes, leather bags and other products to enhance the grade of the products; on plastic products, such as plastic toys, plastic stationery, etc., a good hot-stamping effect can also be achieved; in terms of paper, it is often used for hot-stamping decoration of greeting cards, invitations, book covers, etc.

|

Pneumatic hot stamping Machine//Structure |

||

|

Working table |

High strength Steel plate , size:320*400mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

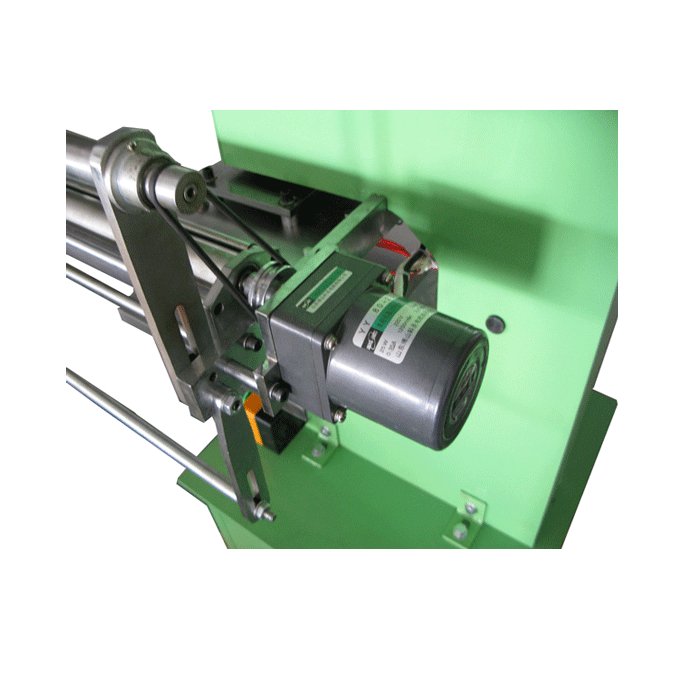

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC1520 |

H-TC1927 |

|

|

|

|

H-TC2129 |

H-TC3025 | |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|

Application︰

Pneumatic hot stamping machines with a pressure of less than 5 tons are light hot stamping machines, which can complete the packaging of paper, leather and some plastic products. Generally speaking, the impression is shallow. The worktable size of this pneumatic hot stamping machine is 320*400mm, which can be adjusted up and down, or pushed and pushed out manually. Due to the large worktable, it is often used for hot stamping paper and leather. This is a very popular hot stamping machine with high cost performance.