Model No.︰H-TC3040LT

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 2912 / pic

Minimum Order︰1 pic

1. Leather embossing machine

• Principle and function: The leather embossing machine mainly uses high temperature and pressure to press the pattern on the leather surface through a mold with a pattern. It can make the leather present various three-dimensional patterns, such as imitation crocodile leather pattern, snake skin pattern, etc., to enhance the texture and beauty of the leather.

• Application scenario: In leather goods manufacturing, for products such as leather bags and belts, embossing can make their appearance more distinctive. For example, when making high-end leather bags, embossing can form exquisite patterns on the surface of the leather bags to enhance the grade of the products.

2. Leather hot stamping machine

• Principle and function: Through the heated hot stamping mold (usually copper or silicone), the metal foil or pigment on the hot stamping paper (a film with metallic luster) is transferred to the leather surface. The leather surface after hot stamping has a shiny metal effect, such as gold, silver, etc., which can highlight the brand logo or decorative pattern.

• Application scenario: In the hot stamping of leather covers, book covers, notebook covers, etc. can be made more gorgeous. For belts, hot stamping can be used to create brand logos or decorative patterns to make the belts more fashionable.

3. Leather cover hot stamping machine

• Features: This machine usually has a precise positioning system, because the leather cover has high requirements for the position accuracy of the hot stamping pattern. It also needs to adapt to leathers of different thicknesses to ensure uniform hot stamping.

• Application advantages: In the production of high-end leather cover products, such as hardcover books, high-end leather notebooks, etc., it can make the text and patterns on the cover (such as book titles, brand logos), etc. present a noble and exquisite effect, attracting the attention of consumers.

4. Belt, leather goods, and leather bags embossing hot stamping machine

• Working method: It combines the two functions of embossing and hot stamping. When working, the belt, leather goods or leather bags are first embossed through the mold to form decorative lines or pattern outlines, and then the hot stamping operation is performed to add the metal effect to the embossed area to make the pattern more three-dimensional and vivid.

• Advantages and effects: This machine can produce complex decorative patterns, such as patterns with metal frames on leather bags, or brand logos with embossing and hot stamping effects on belts. It can effectively improve the quality of product details and make belts, leather goods and bags more competitive in the market.

|

Pneumatic hot stamping Machine//Structure |

||

|

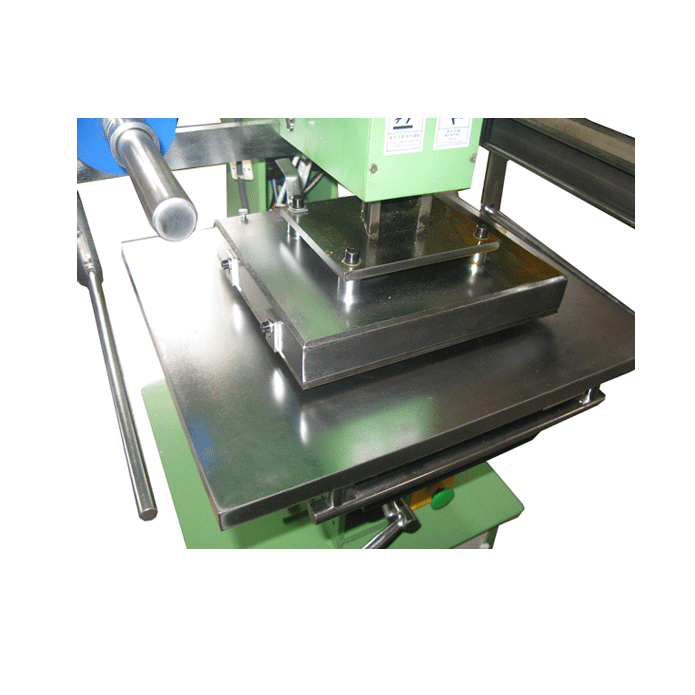

Working table |

High strength Steel plate , size:420*500mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC3030LT |

H-TC3035LT |

|

|

|

|

H-TC3040LT |

H-TC3045LT | |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|

Application︰

When choosing a hot stamping machine, the following factors should be considered:

1) The size of the product

The basic requirement for the size of the product is to be able to place the product on the workbench completely. If your product is relatively small and the products involved in the future are not large, it is not recommended to buy a large-size hot stamping machine. If your product size is relatively Large, but the bronzing area is relatively small, you can consider installing a larger-sized workbench on the small-sized bronzing machine;

2) Bronzing area

The hot stamping area is the most important parameter of the hot stamping machine. The size of the hot stamping plate actually determines the hot stamping area. The larger the hot stamping area, the greater the hot stamping pressure required, and the heating power of the hot stamping machine will increase accordingly;

3) Stamping pressure

If the product requires embossed hot stamping or deep imprints, the pressure requirement for the hot stamping machine is high, and a hydraulic hot stamping machine or a pneumatic hot stamping machine with high pressure should be considered. The hot stamping machine with high pressure has higher requirements for the material selection and structure of the hot stamping machine

4) Security

Choose the hot stamping machine with the workbench in and out to improve safety. If you have higher requirements, you can install a safety grating above the workbench of the hot stamping machine, or install a safety cover on the machine, so that the machine meets European safety standards.

5) Automation

The automation of hot stamping machines is also a development trend in recent years. The workbench adopts a turntable workbench, and the addition of a manipulator, or docking with the front-end production line of the product is the basic requirement for automation.