Model No.︰H-TC6080LPT

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 11470 / pic

Minimum Order︰1 pic

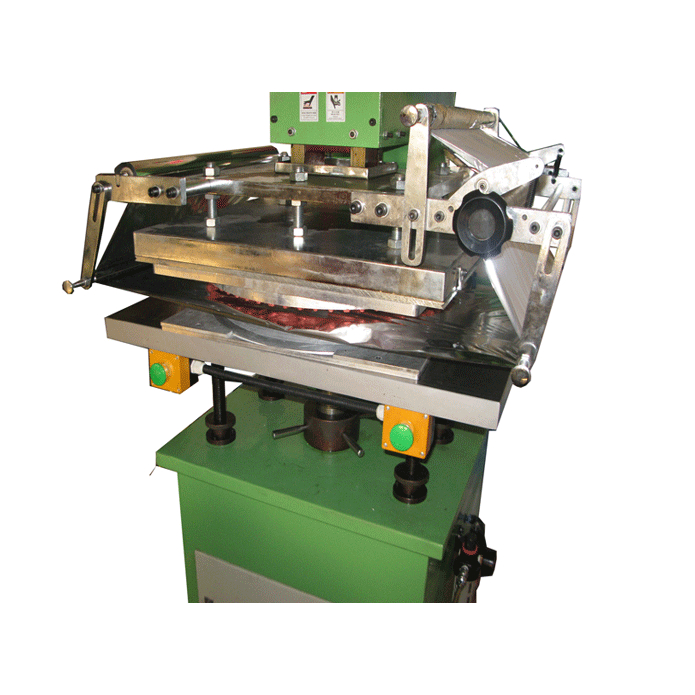

Large decorative door flat pneumatic hot stamping machine:

Equipment features

• Large hot stamping size: To meet the hot stamping needs of large items, the work surface and hot stamping plate area are large, and the hot stamping plate area is 600×800mm.

• High pressure output: Hot stamping of large items requires greater pressure to make the hot stamping firm. The machine adopts pneumatic booster technology or elbow mechanism design to ensure strong pressure, and the maximum pressure can reach 20 tons.

• Accurate temperature control: Equipped with high-quality temperature controller, it can accurately control the temperature of the hot stamping plate to ensure the quality of hot stamping and avoid the effect of too high or too low temperature.

• Flexible workbench adjustment: The workbench can be automatically or manually moved forward and backward, left and right, rotated and adjusted in height, which is easy to operate and adapt to items of different sizes.

Applicable materials

• Large decorative doors: Exquisite patterns and textures, such as imitation wood grain and imitation stone grain, can be hot stamped on its surface to enhance the beauty and grade of the door.

• PVC decorative material board: can be hot-stamped with various colorful and glossy patterns and texts, increase decorativeness and visual effects, and is widely used in interior decoration.

• Large household appliance shell: can be hot-stamped with brand logos, function icons, decorative lines, etc., to enhance the appearance and brand recognition of the product and increase the added value of the product.

• Plastic furniture countertops: hot-stamping can add unique decorative elements, such as floral patterns, geometric patterns, etc., to make the furniture more personalized and artistic.

• Decorative paintings: various beautifully designed patterns can be hot-stamped on the surface of decorative paintings to form a unique visual effect and enrich the types and styles of decorative paintings.

Application advantages

• Improve production efficiency: a high degree of automation, such as automatic paper feeding and paper collection functions, can reduce manual operations and improve production efficiency.

• Ensure stable hot stamping quality: precise control of various parameters to ensure consistent hot stamping effects for each product and improve product quality stability.

• Easy and safe operation: the relay panel is easy to operate and equipped with safety protection devices to reduce the difficulty and risk of operation. Ordinary workers can operate proficiently after training.

|

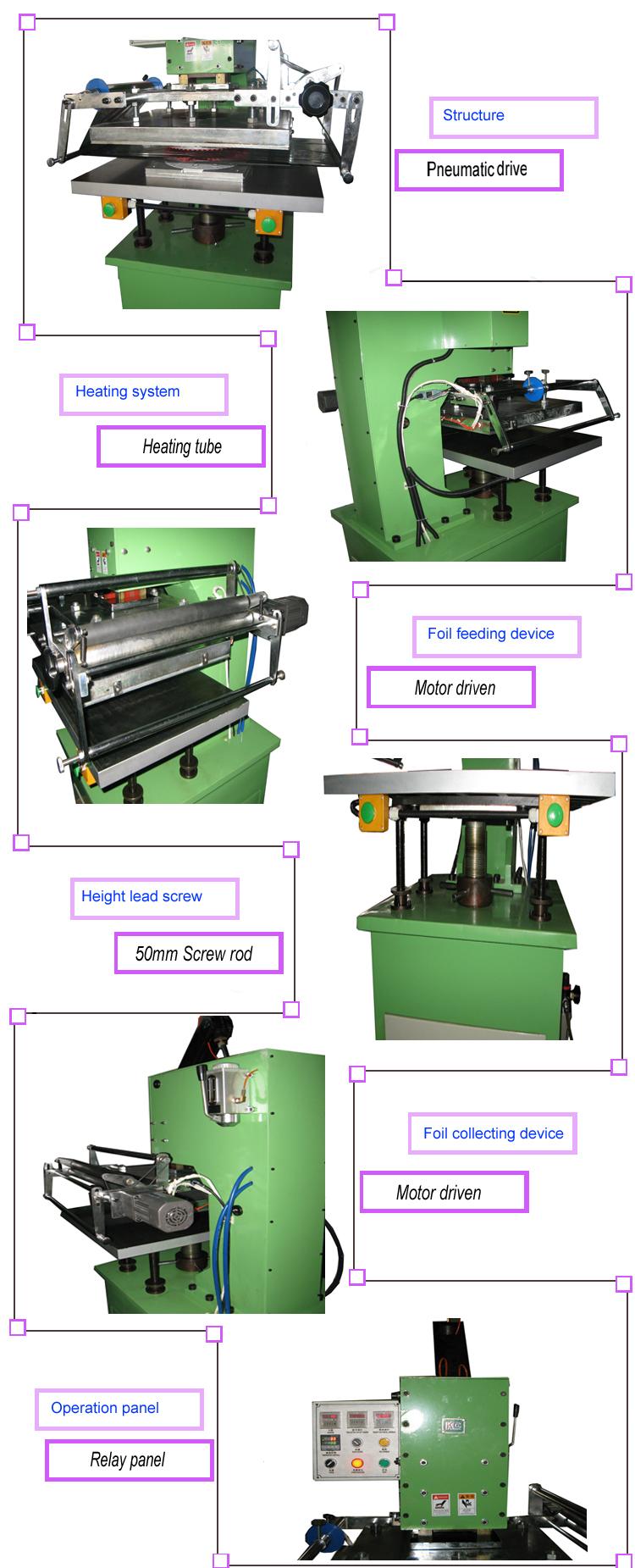

Pneumatic hot stamping Machine //Structure |

||

|

Working table |

High strength Steel plate , size: 650*1000mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC5070LPT |

H-TC6080LPT |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|

Application︰

Die-cutting, concave-convex embossing, hot stamping of some non-planar products may require hot stamping machines with a pressure of more than 10 tons. If customers still choose pneumatic hot stamping machines, they must manufacture high-pressure pneumatic hot stamping machines. High-pressure pneumatic hot stamping machines require The hot stamping machine is made of stronger materials, such as forged No. 45 steel or alloy steel, and the rigidity of the fuselage is better. The quality of the pneumatic components of the machine should be further improved. The pressure of the hot stamping machine mainly refers to the pressure formed by the contact between the hot plate and the product after the hot plate is pressed down. After the workbench and the hot plate are in full contact, the pneumatic device should be able to self-lock and pressurize to ensure that the pressure will not decay during the hot pressing process. , Or lead to deformation of some contact parts, these are the difficulties in manufacturing high-pressure pneumatic hot stamping machines. High-pressure hot stamping machine is widely used in plastic frames, plastic frisbees, automobile safety radiator grilles, trash cans, turnover boxes, and wooden boards.