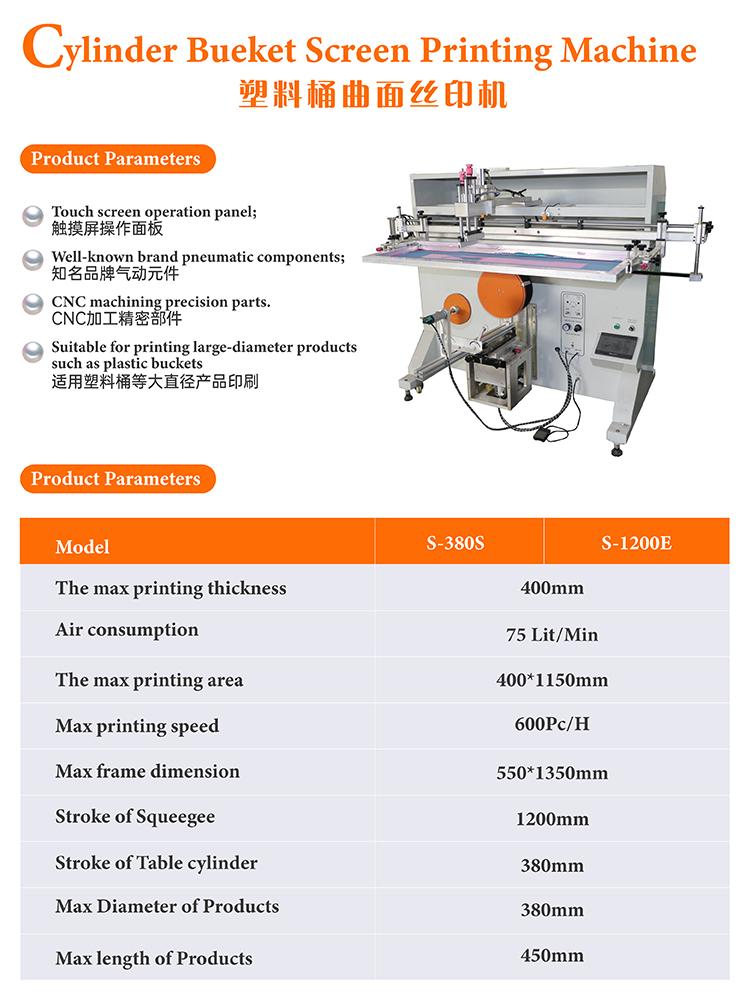

Model No.︰S-380S

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 4588 / pic

Minimum Order︰1 pic

Plastic bucket paint bucket round surface screen printing machine:

Features of adjustable workbench

• Adapt to different bucket heights: Due to the various height specifications of plastic buckets and paint buckets, the design of adjustable workbench is particularly important. The operator can flexibly raise or lower the workbench according to the actual height of the bucket to ensure that the round surface of the bucket can be accurately located in the appropriate position corresponding to the screen printing screen. Whether it is a high-capacity paint bucket or a relatively short small plastic bucket, the screen printing operation can be carried out smoothly, which greatly broadens the scope of application of the equipment.

• Optimize printing pressure and effect: By adjusting the upper and lower positions of the workbench, the distance between the screen printing screen and the barrel surface can be effectively controlled, and the pressure during printing can be adjusted. For example, for a harder plastic bucket, the workbench can be appropriately lowered to increase the fit and pressure between the screen and the barrel surface, so that the ink can be better transferred to the barrel surface through the screen, ensuring clear patterns and full colors; for thinner and softer paint buckets, the workbench can be raised to reduce pressure, avoid deformation of the barrel surface under pressure, and ensure printing quality, which helps to improve the screen printing effect.

Advantages of microcomputer operation

• Accurate parameter setting: The microcomputer operating system can achieve high-precision setting of various parameters of the screen printer. The screen printing speed can be accurately adjusted, and the appropriate scraper movement speed can be determined according to the material of the barrel surface and the complexity of the pattern to ensure uniform transfer of ink; it can also accurately control key parameters such as the pressure of the scraper and the gap between the screen and the barrel surface. When printing fine brand logos or complex decorative patterns, these parameters can be accurately set to ensure that the printing quality reaches a high level.

• Diversified printing mode selection: Its operation interface provides a variety of preset printing modes for selection. For simple monochrome text printing, the quick mode can be selected to improve production efficiency; for patterns that require multi-color overprinting and complex color transitions, switch to high-precision mode, which can accurately control the printing order and superposition effect of each color, ensure the integrity of the pattern and the accuracy of the color, meet different printing needs, and make the screen printer more functional and flexible.

• Real-time status monitoring and feedback: The microcomputer system can display the working status of the screen printer in real time, such as the current number of prints, the operation of each component (including whether the motor speed, scraper position, etc. are normal), and can issue accurate alarm prompt information in time when the equipment fails, which is convenient for operators to quickly locate and solve the problem, ensuring that the screen printing work can be carried out in an orderly manner, improving the reliability and production efficiency of the equipment.

Advantages of screen printing on round surfaces of plastic buckets and paint buckets

• Meet diversified printing needs: Plastic buckets and paint buckets are widely used in many fields such as industry and life, and often have different printing requirements. Some need to be printed with text information such as product names, specifications, warning signs, etc., while others need to present exquisite patterns and brand trademarks to enhance the appearance. With the advantages of adjustable workbench and microcomputer operation, this screen printer can accurately and high-quality complete various round surface printing tasks to meet the diverse needs of different users and industries.

• Ensure printing quality and stability: Screen printing on round plastic buckets and paint buckets is difficult in itself. It is necessary to ensure that the ink is evenly attached and the pattern is not deformed or dislocated due to the curved surface. The screen printer can effectively overcome these problems by reasonably adjusting the height of the workbench to fit the barrel surface, and combining the precise control of the screen printing parameters with microcomputer operation, ensuring that the printed pattern is clear, colorful and firm, and maintaining stable printing quality in different batches of production, enhancing the product's recognition and competitiveness in the market.

In short, this round-surface screen printer with adjustable workbench and microcomputer operation has outstanding advantages for screen printing of round-surface objects such as plastic barrels and paint barrels, and provides a reliable and efficient solution for the appearance decoration and logo printing of related products.

|

S-380S Multi-function screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

|

S-380S Multi-function screen printing Machine //Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

S-380S Multi-function screen printing Machine//Advantage |

|

|

Function |

|

Application︰

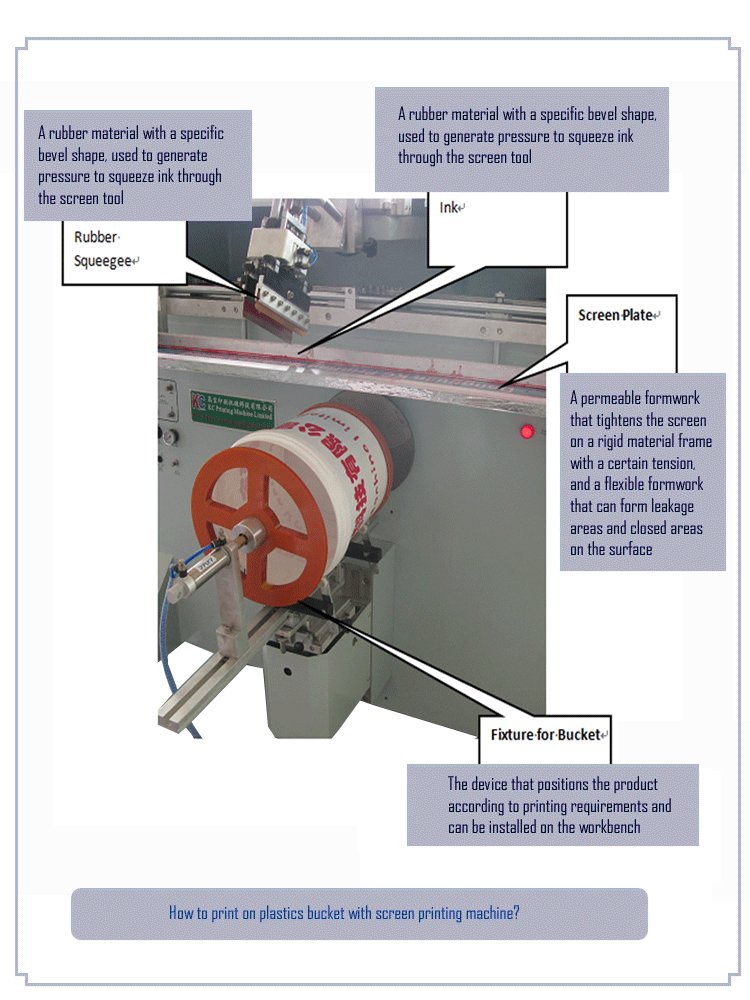

The principle of screen printing of cylinders with a diameter greater than 300mm is the same as that of a small-diameter product screen printing machine, but there are higher requirements for the stability of the screen printing machine. Since the stroke of the scraper is as long as one meter, the error of its movement is maintained. It is very critical. In general, the sliding shaft of the plastic barrel screen printing machine adopts linear guide rails. The plastic barrel and the clamp are heavy, and the structure of the worktable will also be strengthened to a certain extent.