Model No.︰S-125S

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 2100 / pic

Minimum Order︰1 pic

Curved screen printing machine for glass and plastic bottles:

Microcomputer operation

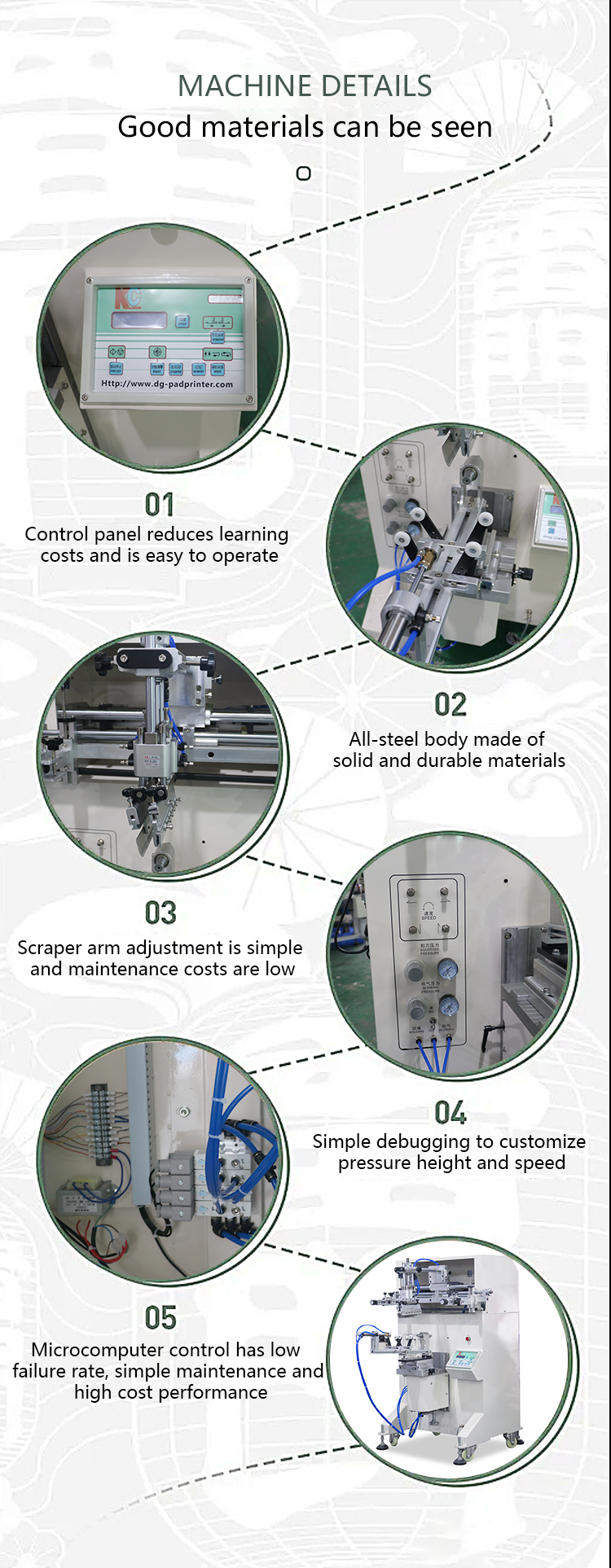

• Accurate parameter setting: Through the microcomputer operating system, the key parameters of the screen printing machine can be accurately set. For example, the screen printing speed, the pressure of the scraper, the distance between the screen and the substrate, etc. can be accurately adjusted to meet the requirements of bottles of different materials, different shapes and different printing patterns. For printing fine brand logos on glass bottles or complex decorative patterns on plastic bottles, the printing quality can be guaranteed by accurately setting parameters.

Multifunctional workbench

• Adaptable to a variety of bottle types: The multifunctional workbench has an adjustable structural feature and can be flexibly adjusted according to different sizes and shapes of glass bottles, plastic bottles, etc. The height, angle and position of the workbench can be changed, so that whether it is a slender glass bottle, a short and fat plastic bottle, or a bottle with a special curved surface, it can be firmly fixed on the workbench, ensuring that the bottle is accurately positioned and will not shake during the screen printing process, laying the foundation for high-quality printing.

• Easy to operate and position: The workbench is often equipped with positioning aids to facilitate operators to quickly and accurately place the bottle in the preset screen printing position. Moreover, when performing operations such as multi-color overprinting that require multiple printings, it can ensure that the bottle can accurately return to the same position every time, effectively avoiding problems such as pattern misalignment and offset, and improving the accuracy and efficiency of printing.

Pneumatic control

• Stable and accurate pressure provision: The pneumatic control system provides stable power for key actions in the screen printing process, such as controlling the movement of the scraper and the lifting and lowering of the screen. Compared with other control methods, pneumatic control can output more accurate and stable pressure to ensure that the scraper evenly scrapes the ink on the screen, so that the ink is evenly transferred to the surface of curved surfaces such as glass bottles and plastic bottles through the screen, achieving a printing effect with uniform color and clear pattern.

• Fast response and adjustment: Pneumatic components have the characteristics of fast response speed. When it is necessary to adjust parameters such as scraper pressure and the degree of fit between the screen and the bottle, they can respond quickly. Operators can quickly adjust according to the actual conditions such as the curvature of the bottle's surface and the thickness of the ink to ensure the smooth progress of the screen printing process, and can complete the switching of printing parameters for different bottles and different patterns in a short time, improving production efficiency.

• Safe and reliable operation: The pneumatic system is relatively simple in structure and highly reliable. It is not easy to malfunction under normal maintenance. In addition, if abnormal pressure occurs during operation, there are corresponding safety protection mechanisms (such as safety valves, etc.) to avoid damage to equipment and operators due to excessive pressure, ensuring the safe and stable operation of the screen printer.

Advantages of application in glass bottles, plastic bottles, and curved surface printing

• Meet diverse needs: Glass bottles and plastic bottles are widely used in the packaging field, and often have a variety of printing needs, such as the need to print exquisite label patterns on beverage bottles, and high-end brand logos and decorative elements on cosmetic bottles. With the precise control of microcomputer operation, the flexible adaptation of the multi-functional workbench, and the stable performance of pneumatic control, this screen printer can complete the printing tasks of different materials and different shapes of bottle surfaces with high quality, meeting the diverse printing needs of the market.

• Ensure printing quality and effect: When screen printing on curved glass bottles and plastic bottles, due to the irregularity of the curved surface, there are high requirements for printing accuracy and ink adhesion. Through the coordinated cooperation of the above-mentioned functional features, the screen printing machine can effectively overcome the difficulties of curved surface printing, ensure that the ink is firmly attached to the surface of the bottle, and the pattern is clear, colorful, and not easy to fade, which improves the appearance quality of the bottle and the overall image of the product and enhances the competitiveness of the product in the market.

|

S-125S Multi-function cylinder screen printing machine//Structure |

|||

|

Working table |

Cylinder workbench/The elliptical cylinder workbench/Flat workbench |

||

|

Actions |

Up-down of working table |

||

|

To be printed |

|

||

|

Squeegee stroke |

Adjust the Limited switch |

||

|

Squeegee and screen plate control |

High precision guide shaft |

||

|

S-125S Multi-function screen printing machine//Usage and characters |

|||

|

Guide |

|

||

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

||

|

S-125S Multi-function screen printing Machine //Parameters |

|||

|

Technical parameters |

|

||

|

Works supply |

|

||

|

Ship parameters |

|

||

|

|||

|

H.S.CODE |

8443198000 |

||

|

Certificate |

CE |

||

|

S-125S Multi-function screen printing Machine//Advantage |

|||

|

Function |

|

||

Application︰

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.