Model No.︰S-185S

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 2857 / pic

Minimum Order︰1 pic

Principle

The microcomputer-controlled multifunctional screen printer uses the principle of screen printing. Pour the ink on the screen, move the scraper on the screen, and let the ink pass through the mesh of the pattern or text on the screen. Then the pneumatic device drives the screen to move left and right, the workbench rises to contact the substrate, and the substrate rotates, so as to transfer the ink to the surface of curved objects such as flashlights, paper towel rolls, and milk bottles.

Structure

• Screen: It consists of a screen and a frame. The screen has a hollow part with patterns or text, and the ink passes through the hollow part. The frame is used to fix the screen to ensure its flatness and stability.

• Scraper: It is usually made of rubber or polyurethane, and its shape and length are adapted to the screen. The function of the scraper is to push the ink to move on the screen so that the ink can pass through the mesh evenly.

• Pneumatic system: It includes cylinders, air pipes, and air valves. The pneumatic system can make the screen or substrate move relative to each other to ensure that the ink is smoothly transferred to the curved object.

• Microcomputer control system: It is the control core of the whole machine. All the actions of the machine can be controlled through the operation panel, making the printing process precise and stable.

• Workbench: It is used to place substrates such as flashlights. The workbench may be equipped with a positioning device to ensure that the object maintains parallel contact with the screen during the printing process.

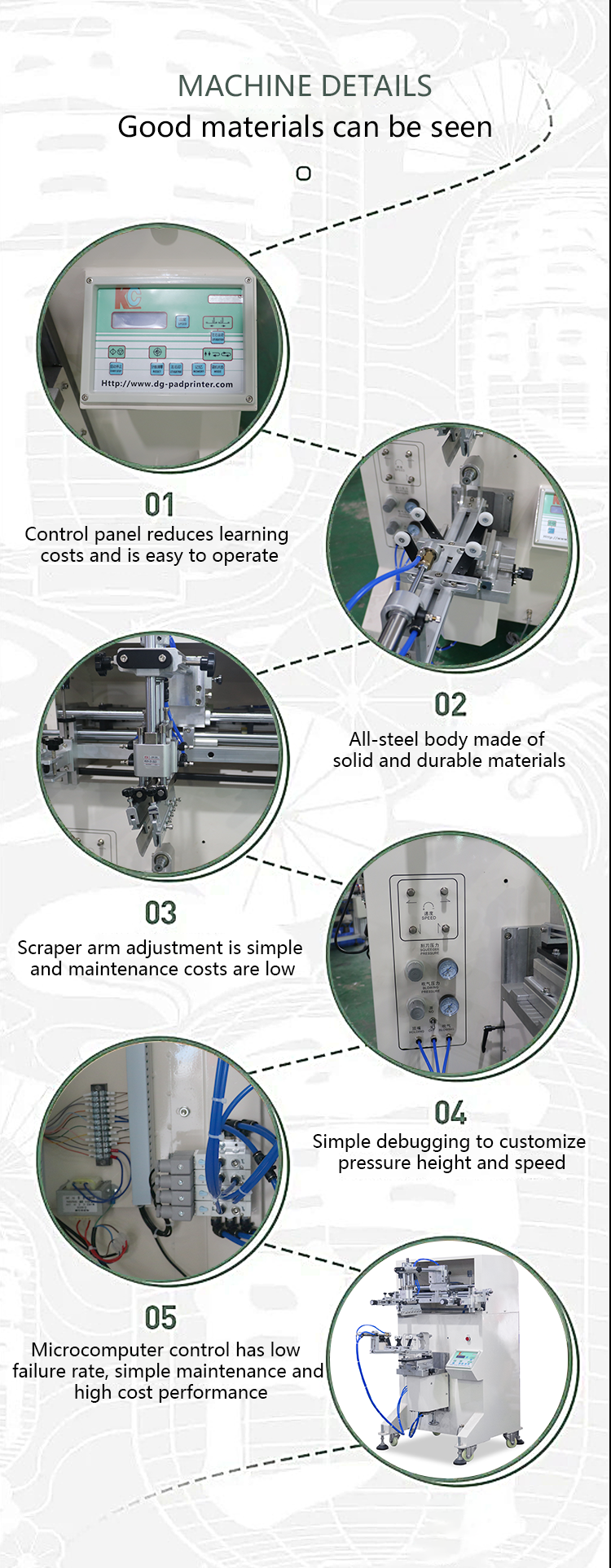

Features

• Strong adaptability to curved surfaces: The pneumatic device can make the screen and the substrate fit well, which is suitable for printing curved objects such as flashlights and milk bottles, ensuring the pattern is complete and clear.

• High printing quality: The microcomputer control system accurately controls the printing parameters to make the ink evenly distributed, the pattern edges clear, and the colors bright.

• Multi-function: The printing parameters can be adjusted according to different substrates and printing requirements to achieve the printing of a variety of patterns and texts.

Uses

• Brand promotion: Print brand logos and slogans on flashlights and paper towel rolls to increase product awareness.

• Decoration and beautification: Print cute patterns on milk bottles to increase the beauty and fun of the product.

|

S-185S Multi-function cylinder screen printing machine//Structure |

|

|

Working table |

Cylinder workbench/The elliptical cylinder workbench/Flat workbench |

|

Actions |

Up-down of working table |

|

To be printed |

|

|

Squeegee stroke |

Adjust the Limited switch |

|

Squeegee and screen plate control |

High precision guide shaft |

|

S-185S Multi-function screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

|

S-185S Multi-function screen printing Machine //Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

S-185S Multi-function screen printing Machine//Advantage |

|

|

Function |

|

Application︰

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.