Model No.︰H-TC80PRB

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 9971 / pic

Minimum Order︰1 pic

Plastic products with a diameter of less than 20mm, such as pen holders, cosmetic pencils, and lipstick tubes, can use semi-automatic hot stamping and heat transfer printing, or full-automatic hot stamping and automatic heat transfer printing machines. Most users will use automatic hot stamping machines and automatic heat transfer machines to decorate their products.

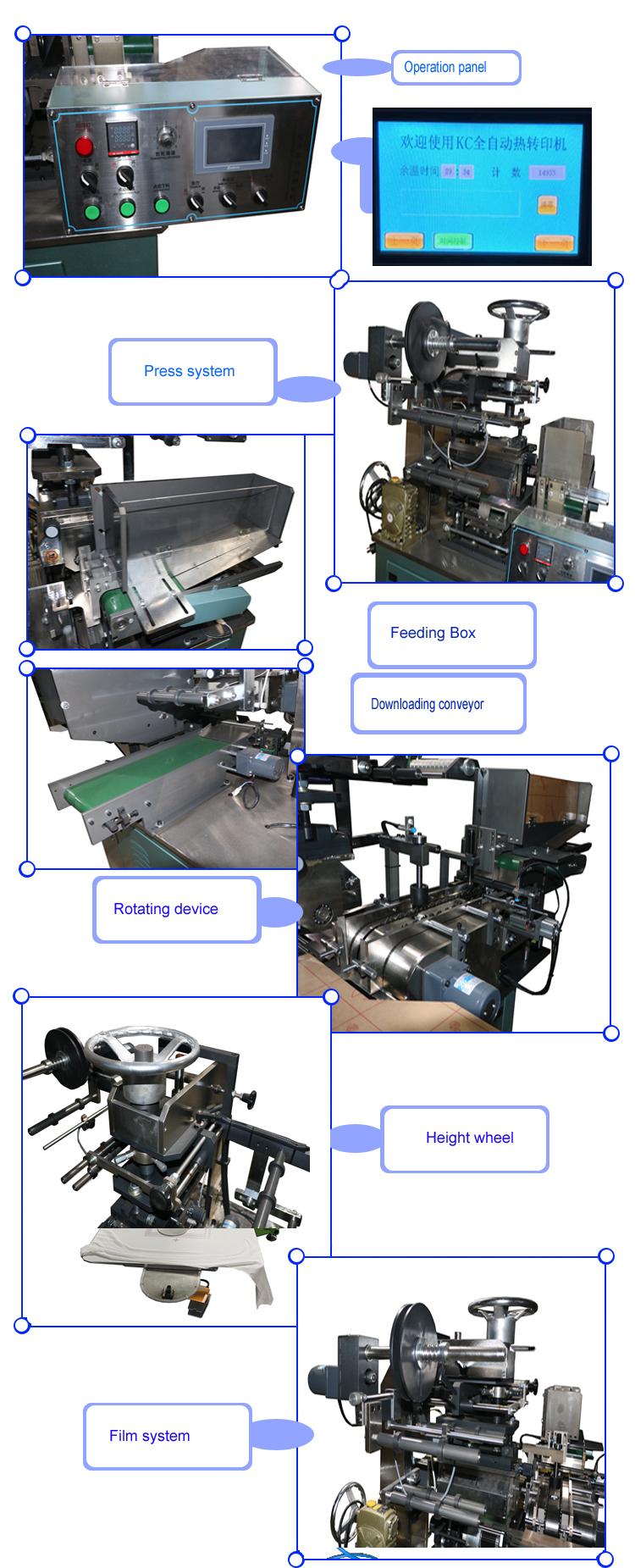

There are various structures of automatic hot stamping machines and automatic heat transfer machines on the market, among which the hot stamping machines with vertical turntable are mostly, because the vertical turntable can transport products continuously, which is more efficient. It uses a feeding trough to store products, and then the products are arranged in a certain order and transported to the hot stamping position. Some products need to be adjusted in direction, and an automatic U-turn device can also be installed. The product is conveyed to the hot stamping station or heat transfer station. Hot stamping generally uses hot stamping paper and anodized aluminum, and thermal transfer generally uses thermal transfer film. Products that have completed hot stamping and thermal transfer printing will continue to run to the unloading position.

The automatic bronzing machine and heat transfer machine for pen holder, makeup pen, lipstick tube are small-sized machine types, in fact, it is a miniature automatic hot stamping machine and heat transfer machine specially designed for small diameter products in order to reduce costs machine, if your product diameter is larger, then you need a bigger machine, but they are similar in structure and have the same function.

Storage Trough

• The storage trough plays an important role in material storage. In the fully automatic pen and marker thermal transfer machine, it can store a large number of pen holders to be transferred, ensuring sufficient material supply during the production process, avoiding production interruptions caused by frequent material replenishment, and enabling the entire thermal transfer process to be carried out continuously and efficiently.

Chain Drive

• The chain drive method provides stable and reliable power transmission for the operation of the machine. It can accurately drive the pen holder to move in an orderly manner between various workstations, such as from the storage trough to the transfer area, and then to the unloading conveyor belt. The characteristics of chain drive are strong carrying capacity and high transmission efficiency. Even if it runs for a long time, it can ensure the accurate transmission position of the pen holder, laying the foundation for the precise implementation of thermal transfer.

Automatic U-turn

• The automatic U-turn function is very clever. Considering that the pen holder may need to be thermally transferred on different sides, it can automatically change the direction of the pen holder. For example, after the thermal transfer of one side of the pen barrel is completed, the automatic U-turn function flips the pen barrel to facilitate the pattern transfer on the other side without manual operation, which greatly improves production efficiency and ensures the accuracy of the transfer pattern position.

Automatic loading

• The automatic loading function further improves the degree of automation of production. It can automatically grab the pen barrel from the storage tank and accurately transport the pen barrel to the starting position of the transfer, reducing the tediousness and error of manual loading, ensuring that each pen barrel can enter the thermal transfer link according to the set process, and improving the overall work efficiency and product quality.

Rubber roller heating system

• The rubber roller heating system is a key part of the thermal transfer process. By heating the rubber roller, the thermal transfer film can better fit the surface of the pen barrel, so that the pattern can be completely and clearly transferred to the pen barrel at a suitable temperature. Different materials of pen barrels may require different heating temperatures. The system can accurately control the temperature to ensure the consistency and high quality of the thermal transfer effect.

Thermal transfer film photoelectric tracking system

• The thermal transfer film photoelectric tracking system has an important monitoring and calibration function. It can monitor the position and status of the thermal transfer film in real time, ensuring that the thermal transfer film is always in the correct position during the transmission process, and the corresponding relationship with the pen holder is accurate. Once the position of the film is found to be deviated, it can be adjusted in time to effectively avoid quality problems such as pattern transfer misalignment and ensure the accuracy of thermal transfer.

Automatic unloading conveyor belt

• The automatic unloading conveyor belt is responsible for conveying the pen holders that have completed thermal transfer in an orderly manner to achieve automatic unloading. It can collect the pen holders neatly for subsequent packaging and other processes. Moreover, the speed and running status of the conveyor belt can be adjusted according to production needs to ensure a smooth and efficient unloading process, which improves the automation level and production efficiency of the entire thermal transfer machine.

Applicable scenarios

• This fully automatic pen holder and marker pen thermal transfer machine is suitable for all kinds of pen holder manufacturers, whether it is producing ordinary writing pens, marker pens, or creative stationery pens, etc., as long as it is necessary to add patterns, logos, decorative elements, etc. on the pen holder through thermal transfer, the machine can be used to efficiently and accurately complete the thermal transfer work, meeting the needs of large-scale production and high requirements for transfer quality.

Usage︰

In diameter, 20mm large and multi-color printed pen products, such as a ballpoint pen, pencil, marker, whiteboard pen, gel pen, pen, pencil, lipstick, medical syringes, bamboo chopsticks and other small-diameter heat transfer decoration of objects designed for fully automatic surface heat transfer machine. The high printing speed, print quality and stability. Automatic loading and unloading, saving labor intensity, and rocker transport mechanism running smoothly.

Technical Parameter︰

|

Items |

Parameter |

|

Products diameter |

6-35mm |

|

Products length |

160mm |

|

Stamping speed |

40-60/min |

|

Machine wattage |

3kw |

|

Outer size |

1250X1150X1450mm |

|

Net weight |

350kg |

|

Power supply |

220v/50hz/60hz |

|

Main motor |

Y902/0.75kw |

|

Film step motor(25K) |

4NM |

|

Roller motor(36K) |

40w |

|

Downloading conveyor motor(75K) |

15w |

|

Downloading motor(100K) |

15w |

|

Film tension motor(50K) |

15w |

|

Heating wattage |

1.8kw |

Production Advantage :

× Chain-type transmission organizations, transmission efficiency, stable operation;

× Can be adjusted depending on the length of the barrel of the width of the trough, and the width of the transmission chain;

× High-speed printing, the normal speed of up to 2500 / h, up to 4000 / h;

× Automatic Foil collecting device, the length of the winding can be flexibly adjusted;

× Additional compressed air dust removal device can be dust in the pen before printing to a minimum;

× Can be adjusted according to different substrates with different temperature, automatic temperature control, to ensure a stable transfer;

× All-electric control, no compressed air;

× Automatic feeding and Laying-off;

× Running smooth and printing stroke, the speed is adjustable;

× Taiwan frequency converter to control the constant torque operation to ensure consistent printing results;

× Hot head height can be flexibly adjusted.

Application︰

The thermal transfer process is a printing process that uses heat and pressure to peel off the pattern printed on the PET or BOPP film and transfer it to the surface of the product. The pattern on the film is usually printed by a gravure printing machine. Because the fine dot reproduction of gravure printing and the expressive power of rich hierarchical images are excellent, the pattern on the film is very beautiful, so the effect of transfer is much better than that of silk printing. The effect is good, which is why thermal transfer is used for decorative effects involving rich colors. The heat transfer process is also one of the best methods for multi-color decoration of round products without anchor points.