Model No.︰SP6-410CRP6DS

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 40000 / pc

Minimum Order︰1 pc

Servo PLC Pad-rotating high-end pad printing machine

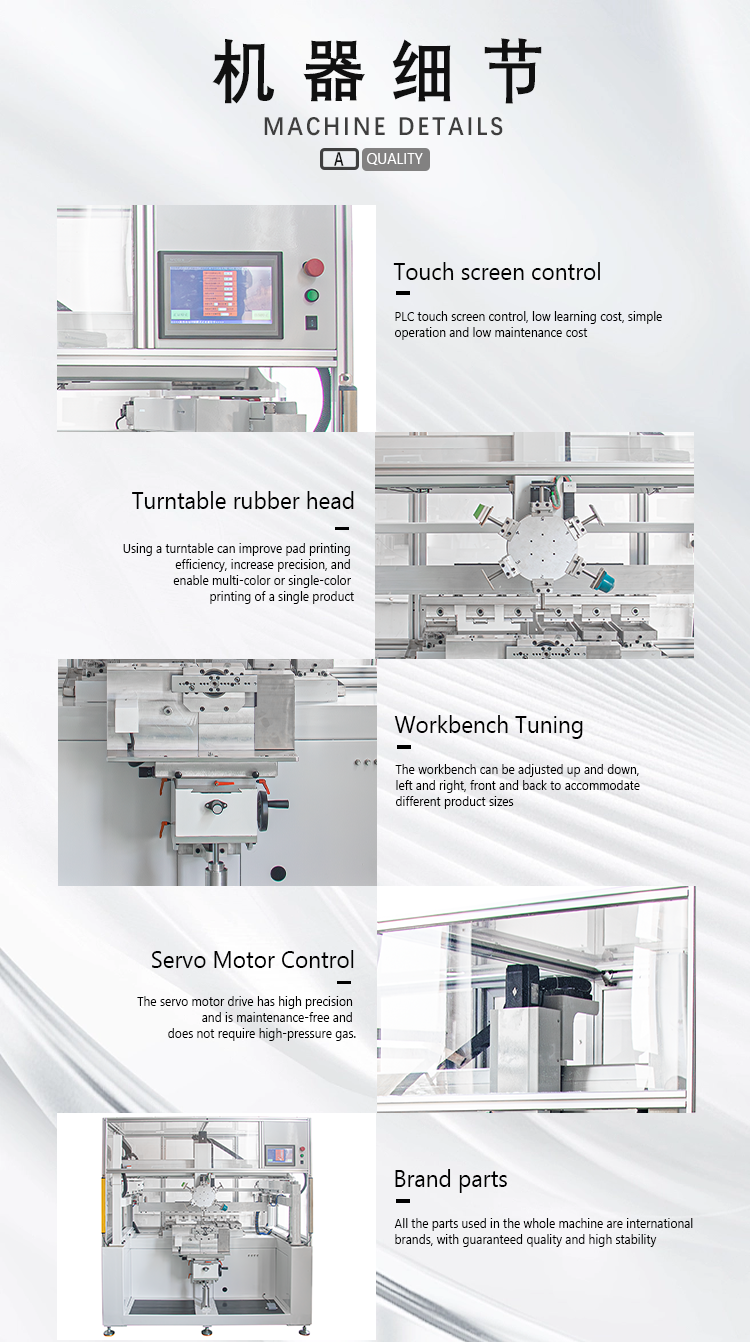

1. Adjustable workbench

• Functional principle: The adjustable workbench can be flexibly adjusted according to the size, shape and printing requirements of different products. It usually uses mechanical structures (such as screws, guide rails, etc.) and electric or manual control devices to adjust the height, angle, horizontal position and other aspects of the workbench. For example, for complex products with irregular shapes, adjusting the angle of the workbench can make the product better adapt to the pad printing process and ensure the integrity and accuracy of the printed pattern.

• Advantages: Improve the versatility of the equipment, can adapt to products of various specifications, and reduce the cost of replacing equipment due to product differences. At the same time, the precise adjustment function helps to improve the printing quality, especially when dealing with complex-shaped products, the printing position can be better controlled.

2. Automatic rotary ink dipping system for rubber head

• Functional principle: The system is mainly composed of a rubber head, a rotating device and an ink dipping mechanism. The rubber head is installed on the rotating device. When ink dipping is required, the rotating device drives the rubber head to rotate accurately to the ink dipping position, and the ink dipping mechanism ensures that the rubber head can evenly dip the appropriate amount of ink. During the ink dipping process, the rotation of the pad head allows all parts of the pad to fully contact the ink, ensuring uniform ink distribution.

• Advantages: Compared with manual ink dipping, the automatic rotary ink dipping system can improve the efficiency and accuracy of ink dipping. Uniform ink distribution helps to print high-quality, color-consistent patterns. Moreover, automated operation reduces the errors and labor intensity of manual operation and improves production efficiency.

3. PLC touch screen operating system

• Functional principle: PLC (Programmable Logic Controller) is the core control unit of the equipment, coordinating the actions of various parts of the pad printer through pre-written programs. The touch screen serves as a human-computer interaction interface. The operator can set various parameters such as printing speed, pad movement trajectory, ink dipping time, etc. by touching the icons, buttons and menus on the screen. At the same time, the touch screen can also display the operating status and fault information of the equipment.

• Advantages: The operation interface is intuitive and friendly, easy for operators to understand and operate. Complex control logic can be implemented to accurately control the working process of the pad printer. It can also store printing parameters of a variety of different products, which is convenient for quick call when producing different products, improving production flexibility and efficiency.

4. Full servo control system

• Functional principle: The full servo control system uses servo motors to drive key components of the pad printer, such as the workbench, pad head, ink dipping mechanism, etc. The servo motor can achieve high-precision position control, speed control and torque control by receiving precise control signals from the PLC. For example, during the movement of the pad head, the servo motor can accurately control the position and movement speed of the pad head to ensure that the pad head can accurately print the pattern at the specified position of the product.

• Advantages: It provides high-precision motion control, allowing the pad printer to meet the printing requirements of complex products, such as excellent performance in the printing of tiny or high-precision patterns. At the same time, the servo control system has the characteristics of fast response speed and high stability, which can improve the production efficiency and printing quality of the equipment.

5. Automatic pad replacement device

• Functional principle: The automatic pad replacement device includes a pad storage unit, a replacement actuator and a positioning mechanism. When the pad needs to be replaced, the replacement actuator takes out a new pad from the storage unit, and then accurately installs it to the pad installation position of the pad printer, and ensures the installation accuracy of the pad through the positioning mechanism.

• Advantages: During the production process, different shapes, sizes or materials of pads may be required according to different products or printing requirements. The automatic pad replacement device can quickly and accurately complete the pad replacement, reducing the time and error of manual pad replacement, improving production efficiency, and can better adapt to the full-function pad printing needs of complex products.

6. CE certification

• Meaning and importance: CE certification is a product safety, health and environmental certification mark, indicating that the pad printer meets the basic requirements of relevant directives and coordinated standards of the European Union. This means that many factors such as mechanical safety, electrical safety, and electromagnetic compatibility are considered during the design and manufacturing process of the product.

• Benefits to users: For users in the European market, pad printers with CE certification can be legally sold and used in EU countries. At the same time, CE certification is also a guarantee of product quality and safety, which makes users more assured during use.

7. Full-function pad printer for complex products

• Features and application scenarios: This pad printer has multiple functions and can cope with products with various complex shapes and printing requirements. It can be used to print products of various materials, such as plastics, metals, ceramics, etc. It plays an important role in the surface printing of complex products such as electronic product shells, auto parts, toys, etc., and can print high-quality text, patterns, logos, etc. For example, in the printing of automotive interior parts, it can accurately print exquisite patterns and brand logos on plastic parts with complex curved surfaces.

|

Six colors Pad-rotating servo pad printer //Structure |

||

|

Feeding |

Manual |

|

|

Working table |

Three-dimension working table |

|

|

Ink supply system |

Closed -type system |

|

|

Plate type and size |

10mm Thick steel plate. Size :100*250mm. |

|

|

Pad control |

Automatic rotating, servo driven, Automatic rubber pad clean device |

|

|

Ink drying |

Heat air |

|

|

Six colors pad rotating closed cup pad printer with servo and pad clean device//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

Six colors sealed cup pad printer with servo shuttle and pad clean device //Parameter |

||

|

Technical parameters |

SP6-410DCSP |

SP6-614DCSP |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certicate |

CE |

|

|

Six colors closed cup pad printer with servo shuttle and pad clean device //Advantage |

||

|

Function |

|

|