Model No.︰SM12-5050

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 4411 / pic

Minimum Order︰1 pic

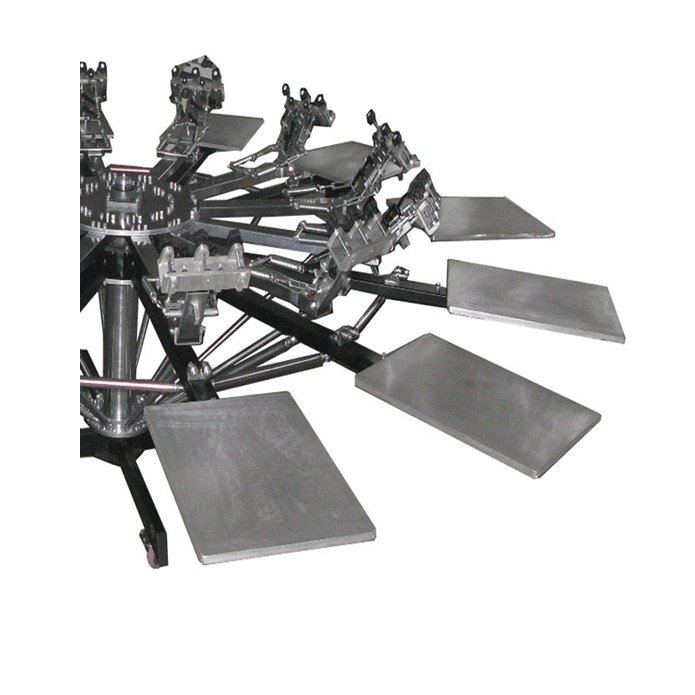

The manual screen printing machine can do up to 12 colors. The more colors, the more difficult it is to manufacture the machine. 12 screen plates and 12 worktables rotate around a central axis, which has higher strength and overprinting accuracy of the machine. Therefore, the structure of the machine must be strong, and the design must be reasonable. Since it is manual operation, the rotation flexibility of the screen rotation and the worktable must be good, which is a requirement to reduce the labor intensity of the operator. Precision grinding of seamless steel pipes, high-strength support rods, brand-name bearings, strict assembly procedures and inspection procedures will ensure that the 12-color screen printing machine can print on the T-shirts perfectly.

|

SM12-5050 Manual 12-color garment screen printing machine//Structure |

|

|

Working table |

High strength cast aluminum plate -500*500mm |

|

Actions |

Rotating working table and rotating screen plate |

|

To be printed |

|

|

Rotating angle |

30 |

|

Squeegee and screen plate control |

High precision rotating disc |

|

Ink drying |

Heat set ink, IR Drying |

|

SM12-5050 Manual 12-color Garment screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

|

|

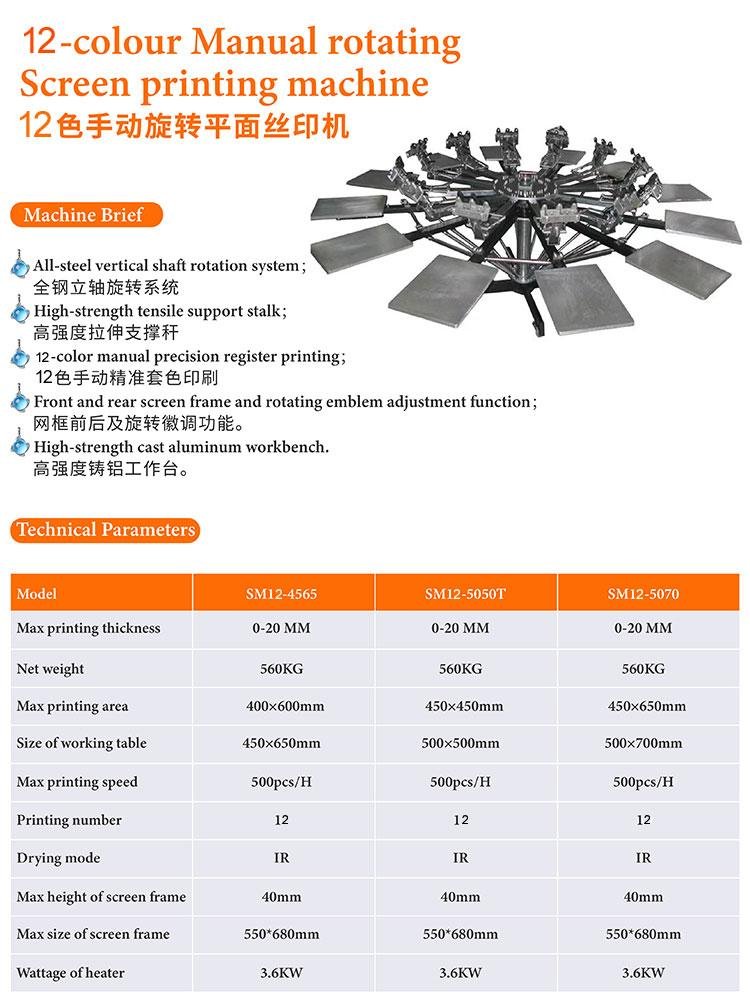

SM12-5050 Manual 12-color garment screen printing Machine //Parameters |

|

|

Technical parameters |

SM12-5050T 12-colour Manual-operating rotating flat screen printing machine

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

SM12-5050 Manual 12-color garment screen printing machine//Advantage |

|

|

Function |

|

Updated ︰ 220V/110V/50HZ/60HZ/1-PHASE

Application︰

There are many structures of screen printers, but you will find that the structure of screen printers for printing clothing pieces is very different from that of screen printers for printing plastic, paper, glass and other products. Screen printers for fabric pieces are usually designed in a form where the screen and printing head rotate around the central axis, similar to an octopus. We call this type of screen printer an octopus screen printer.

1) The workbench generally uses a flat aluminum plate, on which glue can be applied during printing. The glue can bond the clothing pieces to the workbench to prevent movement;

2) The screen and workbench of a manual screen printer will rotate around the central axis to achieve multi-color screen printing. The automatic screen printing machine table keeps rotating to achieve multi-color screen printing;

3) The printing device generally adopts front and back scraping printing, which makes it easier to place products, check products, and achieve multi-color accurate overprinting;

4) A swing drying device is usually set between printing stations to facilitate the drying of the ink layer and prevent the next color printing from causing ink color bleeding;

5) The drying device on the screen printing machine often only dries the ink layer on the surface and dries it thoroughly. A separate tunnel drying furnace can be used for drying, which can improve production efficiency.

Screen printing machines face fierce competition from printers. Printers have developed rapidly due to the lack of complex processes such as plate making and color matching, but they are still difficult to compare with screen printing machines in terms of three-dimensional patterns and bright colors with very strong surface power. They play a powerful role in clothing printing in the market.