Model No.︰H-TAR

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 22264 / pic

Minimum Order︰1 pic

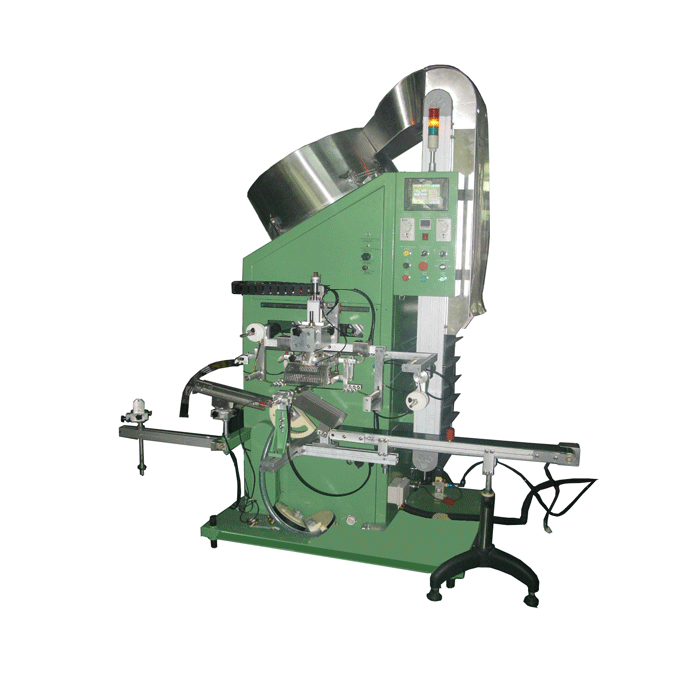

Automatic bottle-caps Golden-sliver line hot stamping machine

The role of hot stamping of gold and silver lines at the opening of cosmetics caps:

Beautiful decoration

• Gold and silver lines can add a gorgeous and exquisite feeling to cosmetics caps. This decorative effect can make cosmetics stand out from many products and attract consumers' attention. For example, the caps of some high-end brands of lipsticks and face creams look more textured and high-end after hot stamping of gold or silver lines.

Brand differentiation and identification

• Cosmetics of different brands can be distinguished by unique gold and silver line designs. Details such as the shape, thickness, position or number of lines can be used as the iconic features of the brand. For example, a certain brand has always used a double gold line design at the opening of the cap, and consumers can quickly identify the brand when they see this feature.

Anti-counterfeiting function

• Complex and delicate gold and silver line patterns can be used as an anti-counterfeiting method. Because these patterns have certain difficulties in the production process, it is difficult for criminals to copy. Some brands will use special gold or silver line hot stamping technology, such as laser gold line hot stamping. This kind of gold line with special optical effects is difficult to be counterfeited, thus helping consumers to distinguish the authenticity of the product.

Machine introduction

1. Working Principle

• This hot stamping machine mainly works by heat pressing. The heating device inside the machine heats the hot stamping plate to a certain temperature. When the cosmetic bottle cap or bottle mouth is automatically transported to the hot stamping position, the hot stamping plate contacts the bottle cap or bottle mouth under a certain pressure. At this time, the metal layer on the hot stamping foil (with gold and silver thread patterns) is transferred to the surface of the bottle cap or bottle mouth under the action of high temperature and high pressure, thus forming a beautiful gold and silver thread pattern.

2. Automation Features

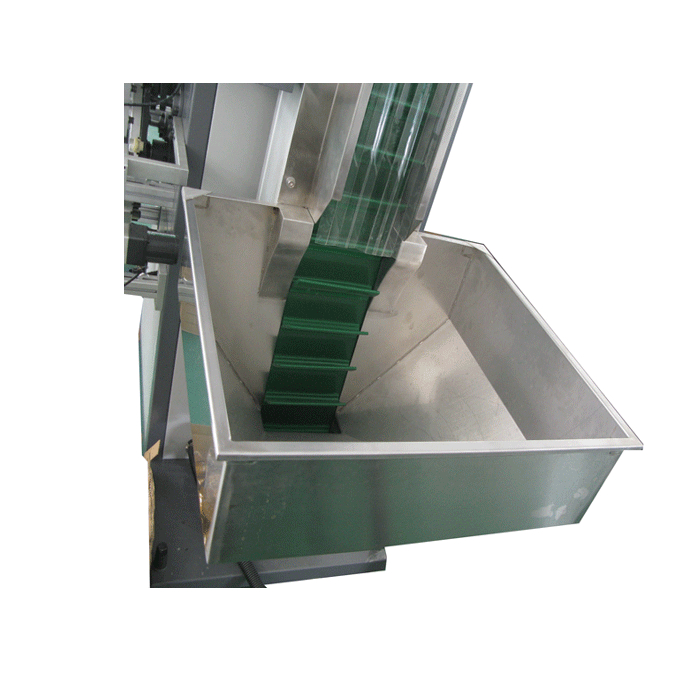

• Automatic feeding: There is a special feeding system that can accurately deliver the cosmetic bottle cap or bottle mouth to the hot stamping area at a preset speed and sequence, ensuring the continuity of production. For example, the feeding is carried out by means of conveyor belts or robotic arms, and can be appropriately adjusted according to the size and shape of the bottle cap.

• Automatic positioning: Through high-precision sensors and positioning systems, the position of the bottle cap or bottle mouth is ensured to be accurate during hot stamping. This can ensure the consistency of the position of the gold and silver thread pattern, avoid pattern deviation, and make the hot stamping effect of each product meet the standard.

• Automatic parameter adjustment: The key parameters such as the temperature, pressure and time of hot stamping can be automatically adjusted according to the different materials of cosmetic bottle caps (such as plastic, glass, etc.) and the type of hot stamping foil. For example, for plastic bottle caps and glass bottle caps, the machine can automatically adjust to the appropriate temperature and pressure to achieve the best hot stamping effect.

3. Advantages

• Improve production efficiency: Fully automated operation greatly speeds up production and can complete the hot stamping of a large number of cosmetic bottle caps in a short time. Compared with manual hot stamping, the efficiency can be increased several times or even dozens of times.

• Ensure product quality: Due to the high precision of automated control, the quality of hot stamping patterns is more stable. The lines of gold and silver lines are clear and the color is uniform, which can improve the appearance quality and grade of cosmetic products.

• Save labor costs: Reduce dependence on manual operations, reduce labor costs and quality problems caused by human factors.

|

Full automatic cap-side Line-type hot stamping Machine //Structure |

|

|

Feeding |

Crawling robot |

|

Initial position |

Sensor control , Guide rail |

|

Working table |

8 stations rotating disk, index plate control |

|

Surface treatment |

Heat air |

|

Top-bottom identification |

Sensor and Machine device |

|

Press |

Vertical press |

|

Temperature control |

IR Heater, automatically controlling |

|

Foil collecting |

Automatically collecting |

|

Blanking |

Automatically |

|

Full automatic cap side line-type hot stamping machine //Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

Full automatic cap-side hot stamping Machine //Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

Full automatic cap-side hot stamping machine //Advantage |

|

|

Function |

|

Application︰

Most of the containers need to be closed with lids to achieve the purpose of long-term preservation of products. The hot stamping of lids is also a decoration issue that is generally concerned in the industry. The hot stamping of lids is divided into side stamping and top stamping. The structure of the machine is roughly the same, except that During the process, the hot stamping on the top of the bottle cap adopts flat stamping, and the ironing head only moves up and down, while the hot stamping on the side of the bottle cap requires the rotation of the fixture and the left and right movement of the ironing head.

Automatic bottle cap hot stamping usually consists of automatic crawler feeding system, prepress processing system, positioning system, workbench, hot stamping system, and automatic unloading system. Because bottles and bottle caps are widely used in all aspects of life and are used in large quantities, the speed requirements for automatic hot stamping machines are very high. It is widely used in plastic packaging, medicine, cosmetics, stationery, wine, washing supplies and other industries.