Model No.︰SA4-4560/10

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 22300 / pic

Minimum Order︰1 pic

Cost-effective fully automatic turntable T-shirt octopus screen printer:

Principle

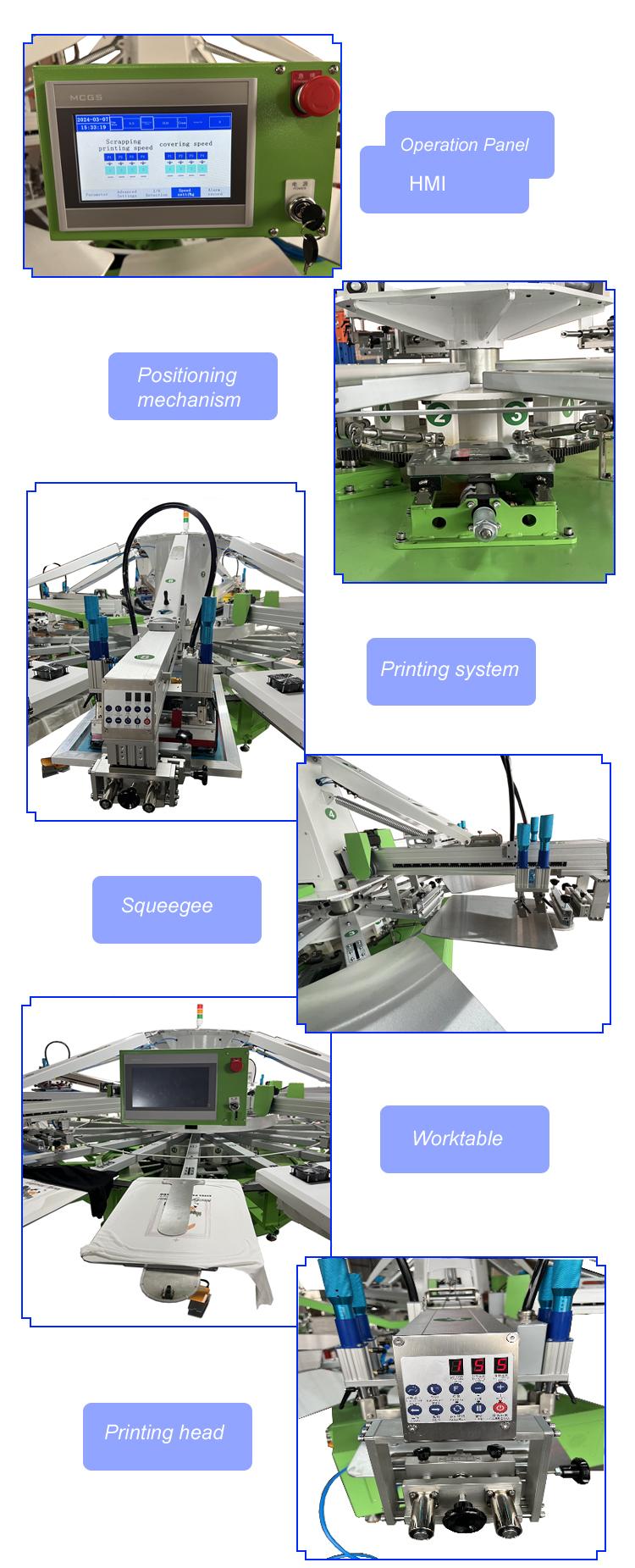

The fully automatic turntable T-shirt octopus screen printer is mainly composed of workbenches with different numbers of stations arranged around the central axis and arranged evenly at equal angles. A certain number of screens that can also rotate around the central axis fall after the rotation angle set by the PLC, and contact the substrate for printing after positioning, and print the pattern to be printed on the product surface. The screen printer is generally equipped with an IR drying oven on the interval station to dry the surface to ensure the continuous multi-color overprinting.

Advantages

• High efficiency: With high automation, it can automatically complete the processes of positioning, printing, drying, and discharging. It can print 300-500 T-shirts per hour, and its production efficiency far exceeds that of manual and semi-automatic screen printers.

• High precision: It adopts advanced positioning system and precision mechanical structure to ensure accurate pattern printing position, accurate multi-color printing color registration, clear printed patterns, bright colors, and stable quality.

• Easy operation: It is usually equipped with an intuitive operation interface and an easy-to-understand control system. Operators can operate proficiently after short-term training, reducing the dependence on professional technicians.

• Cost saving: Improve production efficiency, reduce labor input and labor intensity, and reduce labor costs; the equipment has high stability, low maintenance cost, and can reduce the waste of materials such as ink, reducing production costs.

• Strong applicability: It can print T-shirts of different sizes and materials. By replacing the screen printing plate and adjusting related parameters, it can also be used for printing other flat or nearly flat objects to meet diversified production needs.

• Small footprint: compact structure and reasonable design, such as a small device with a diameter of 5 meters, which occupies a small space and is suitable for use in places with limited space such as small and medium-sized enterprises and small studios.

Scope of application:

• Clothing and accessories: It can print patterns and texts on various T-shirts, sportswear and other clothing. It is also suitable for clothing accessories such as handkerchiefs, scarves, socks, etc., which can meet the printing needs of clothing in different seasons, styles and styles.

• Luggage and handbags: such as backpacks, handbags, wallets and other luggage products, brand logos, patterns, etc. can be printed on their surfaces to enhance the beauty and recognition of the products.

• Home textile products: tablecloths, curtains, pillowcases and other home textile products can also be printed with this screen printer to add personalized decorative elements to meet the needs of different consumers for home styles.

• Non-woven fabrics and industrial fabrics: Printing patterns on non-woven fabrics can be used to make eco-friendly bags, advertising materials, etc.; printing marks and logos on industrial fabrics can help improve production management efficiency and product quality tracking.

• Other special materials: It can also be used for printing daily necessities such as umbrellas, towels, bath towels, and special materials such as yoga mats and mouse pads to achieve a variety of patterns and color effects.

|

SA4-4560/10 Automatically 4-color garment screen printing machine//Structure |

||

|

Location |

Sensor |

|

|

Working table |

High strength cast aluminum plate -450*650mm |

|

|

Actions |

automatically Rotating screen plate |

|

|

To be printed |

|

|

|

Rotating angle |

45 |

|

|

Squeegee and screen plate control |

High precision rotating disc |

|

|

Ink drying |

Heat set ink, IR Drying |

|

|

SA4-4560/10 automatically -color Garment screen printing machine//Usage and characters |

||

|

Guide |

|

|

|

Application |

|

|

|

SA4-4560/10 Automatically 4-color garment screen printing Machine //Parameters |

||

|

Technical parameters |

SA4-4560/10 4-colour automatically rotating flat screen printing machine

|

|

|

SA6-4570/14 6-colour automatically rotating flat screen printing machine

|

||

|

Works supply |

|

|

|

Package parameters |

|

|

|

H.S.CODE |

8443198000 |

|

|

Certificate |

CE |

|

Machine advantage

Application︰

The automation of garment cutting screen printing machines is also a market trend. In terms of overprinting accuracy and ease of operation, the oval automatic screen printing machine has certain advantages, but it occupies a large area and costs high. For small and medium garment printing factories , The octopus-style multi-color screen printing machine still has a large market space. The multi-color octopus screen printing machine adopts manual loading, that is, the materials and clothing are placed on the workbench by hand. The workbench can have 8-10-12-14 or more according to the number of colors of the machine, and some stations are used for For silk screen printing, some stations are used for drying. In principle, the stations need to be installed with a swing oven to ensure that the surface of the ink is dry and avoid the phenomenon of sticking between colors. The workbench of the screen printing machine can automatically rotate to the next screen printing position to print the next color. In order to improve the accuracy, the screen printing machine adopts a certain mechanical positioning device. At the same time, the upper and lower sides of the screen are controlled by servo motors.

The automatic rotary cutting screen printing machine is another representative of the forward and backward movement of the scraper in the type of screen printing machine. We know that the oblique arm screen printing machine is such a structure, which makes it easier to place and remove products. If you are tired of the hard work of manual screen printing machines and do not plan to buy oval screen printing machines, then you can consider disc screen printing machines.

Base structure︰

There are many structures of screen printers, but you will find that the structure of screen printers for printing clothing pieces is very different from that of screen printers for printing plastic, paper, glass and other products. Screen printers for fabric pieces are usually designed in a form where the screen and printing head rotate around the central axis, similar to an octopus. We call this type of screen printer an octopus screen printer.

1) The workbench generally uses a flat aluminum plate, on which glue can be applied during printing. The glue can bond the clothing pieces to the workbench to prevent movement;

2) The screen and workbench of a manual screen printer will rotate around the central axis to achieve multi-color screen printing. The automatic screen printing machine table keeps rotating to achieve multi-color screen printing;

3) The printing device generally adopts front and back scraping printing, which makes it easier to place products, check products, and achieve multi-color accurate overprinting;

4) A swing drying device is usually set between printing stations to facilitate the drying of the ink layer and prevent the next color printing from causing ink color bleeding;

5) The drying device on the screen printing machine often only dries the ink layer on the surface and dries it thoroughly. A separate tunnel drying furnace can be used for drying, which can improve production efficiency.

Screen printing machines face fierce competition from printers. Printers have developed rapidly due to the lack of complex processes such as plate making and color matching, but they are still difficult to compare with screen printing machines in terms of three-dimensional patterns and bright colors with very strong surface power. They play a powerful role in clothing printing in the market.