Model No.︰H-TC4050LPT

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 8235 / pic

Minimum Order︰1 pic

Reasons for high-pressure flat hot stamping machine

When hot stamping is required on large areas, hard materials or uneven surfaces, a high-pressure flat hot stamping machine is needed to ensure that the hot stamping pattern is transferred completely and clearly. For example, when hot stamping on thick wooden boards, large metal plates or textured leather, sufficient pressure is required to make the hot stamping foil fully contact the material to achieve the ideal hot stamping effect.

Uses of high-pressure flat hot stamping machine

It is mainly used for hot stamping needs of large or special materials, such as hot stamping of large wooden door panels and metal signboards in building decoration materials, as well as hot stamping of automotive interior parts such as seat leather, instrument panels, etc., and scales on clock dials. It is also often used for hot stamping of high-end gift boxes, display props and other products.

Features of high-pressure flat hot stamping machine

• High and uniform pressure: It can provide stable and uniform pressure on a large area to ensure the quality of hot stamping.

• Strong adaptability: It can handle a variety of materials, including hard, thick, rough materials, etc.

• Large hot stamping area: Suitable for large-area hot stamping, reducing splicing marks and improving production efficiency.

Differences from ordinary hot stamping machines

• Pressure: Ordinary hot stamping machines have low pressure and are suitable for hot stamping thin, soft, and small-area materials, such as paper, thin plastic, etc.; high-pressure flat hot stamping machines have high pressure and can handle large sizes and hard materials.

• Applicable materials: Ordinary hot stamping machines have narrow material adaptability, while high-pressure flat hot stamping machines are widely applicable to various complex materials.

• Hot stamping effect: Ordinary hot stamping machines may have problems such as incomplete hot stamping and blurred patterns on large areas or hard materials; high-pressure flat hot stamping machines can ensure clear and complete patterns with higher quality.

|

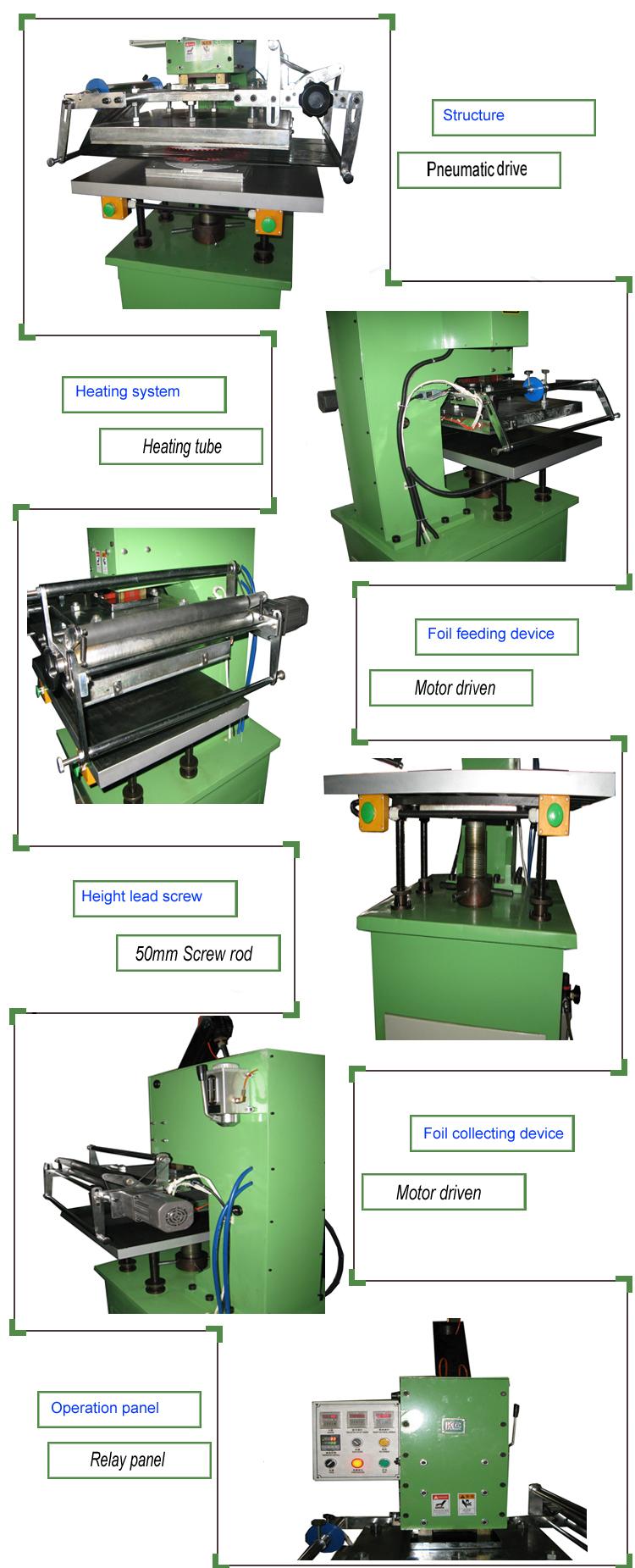

Pneumatic hot stamping Machine //Structure |

||

|

Working table |

High strength Steel plate , size: 520*800mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC4050LPT |

H-TC4060LPT |

| 1. Hot plate area:400×500 mm

2. Working table area:800 ×520mm 3. Max printing pressure:15,000 Kg 4. Up and down distance:70mm 5. Heat wattage: 6×800W 6. Foil in feed: Motor Drive 7. Temperature adjustment:0-300oC 。 |

1. Hot plate area:400×600 mm

2. Working table area:800 ×520mm 3. Max printing pressure:15,000 Kg 4. Up and down distance:70mm 5. Heat wattage: 6×800W 6. Foil in feed: Motor Drive 7. Temperature adjustment:0-300oC 。 |

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|

Application︰

Die-cutting, concave-convex embossing, hot stamping of some non-planar products may require hot stamping machines with a pressure of more than 10 tons. If customers still choose pneumatic hot stamping machines, they must manufacture high-pressure pneumatic hot stamping machines. High-pressure pneumatic hot stamping machines require The hot stamping machine is made of stronger materials, such as forged No. 45 steel or alloy steel, and the rigidity of the fuselage is better. The quality of the pneumatic components of the machine should be further improved. The pressure of the hot stamping machine mainly refers to the pressure formed by the contact between the hot plate and the product after the hot plate is pressed down. After the workbench and the hot plate are in full contact, the pneumatic device should be able to self-lock and pressurize to ensure that the pressure will not decay during the hot pressing process. , Or lead to deformation of some contact parts, these are the difficulties in manufacturing high-pressure pneumatic hot stamping machines. High-pressure hot stamping machine is widely used in plastic frames, plastic frisbees, automobile safety radiator grilles, trash cans, turnover boxes, and wooden boards.