Model No.︰HH-TC4050LPT

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 11176 / pic

Minimum Order︰1 pic

Wooden wine box hot stamping machine:

High-strength hot stamping plate and workbench

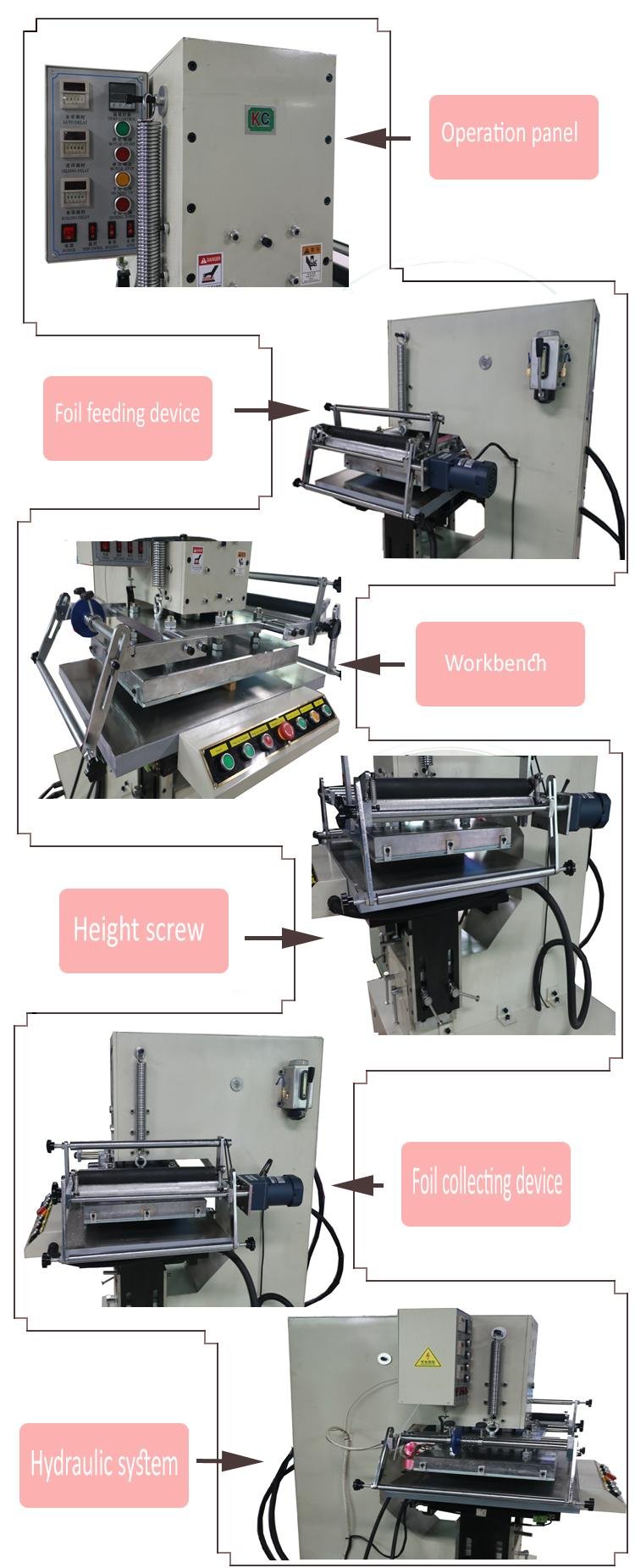

• Structural features:

• Hot stamping plate: Made of special high-strength material, it has good thermal conductivity and high temperature resistance. It can maintain structural stability and is not easy to deform in a long-term high-temperature working environment. Its surface is usually finely processed to ensure high flatness, so that when it comes into contact with the color box or wooden wine box for hot stamping, it can evenly transfer heat and pressure, so that the hot stamping foil can better adhere to the surface of the box body and achieve high-quality hot stamping effect.

• Workbench: It also has a high-strength structure to provide stable support for placing color boxes or wooden wine boxes. The flatness of the workbench is strictly controlled to ensure that the box body is placed stably, and its size design can adapt to color boxes and wine boxes of different sizes, which is convenient for operation and use. In addition, there may be some positioning devices on the surface of the workbench to facilitate the accurate determination of the position of the box body and improve the accuracy of the hot stamping position.

• Advantages: The high-strength hot plate and workbench combination lays a solid foundation for the hot stamping operation, ensuring that a stable working state can be maintained during repeated hot stamping processes, reducing quality problems such as uneven hot stamping and unclear patterns caused by factors such as component deformation, and helping to improve the qualified rate and overall quality of hot stamping products.

Hydraulic drive system

• Working principle:

Hydraulic oil is used as the medium for transmitting power, and the hydraulic oil is pressurized by the hydraulic pump and delivered to each actuator (such as a hydraulic cylinder, etc.). In the hot stamping machine, the hydraulic drive system is mainly used to drive the hot plate to move up and down. When the hot stamping operation is started, the high-pressure oil output by the hydraulic pump pushes the piston of the hydraulic cylinder downward, thereby driving the hot plate to press against the color box or wooden wine box placed on the workbench, applying stable and sufficient pressure to make the hot stamping foil fit tightly to the surface of the box body, completing the hot stamping transfer; after the operation is completed, the hydraulic oil returns, and the piston drives the hot plate to rise and reset.

• Advantages:

Hydraulic drive can provide a large driving force to ensure that there is sufficient pressure between the hot plate and the box body to achieve a good hot stamping effect, especially for hard substrates such as wooden wine boxes, which can ensure that the hot stamping foil is firmly attached to them. Moreover, the hydraulic system has good stability and adjustability. It can flexibly adjust the pressure of the hot plate according to the color boxes and wine boxes of different materials and thicknesses, accurately control the hot stamping process parameters, and the operation process is relatively stable, reducing the hot stamping defects caused by pressure fluctuations.

Relay panel operation

• Operation mode and function:

The relay panel is an operation interface for human-computer interaction, and it is equipped with multiple control buttons, switches and indicator lights. The operator can control the hot stamping machine's start, stop, hot stamping time setting, hydraulic drive system pressure adjustment and other functions by pressing the corresponding button or toggling the switch. The indicator light is used to display the different operating states of the equipment, such as whether the power is on, whether the hydraulic system is working normally, whether the hot stamping operation is in progress, etc., so that the operator can intuitively understand the equipment situation and find and deal with problems in time.

• Advantages:

This operation method is simple and easy to understand. It does not require the operator to have complex professional technical knowledge and is easy to use. Through the relay panel, the functions of each part of the hot stamping machine can be conveniently controlled, and the hot stamping parameters can be quickly adjusted to adapt to different production needs and improve production efficiency. In addition, the relay has the characteristics of high reliability and strong stability, which can ensure long-term stable control of equipment operation and reduce the situation where production is affected by failures in the operation control link.

This hot stamping machine for color boxes and wooden wine boxes relies on high-strength hot plates and workbenches to ensure the quality of hot stamping. The hydraulic drive system provides stable and effective power. Coupled with the convenient relay panel operation, it can achieve the hot stamping operation of color boxes and wooden wine boxes efficiently and stably, meeting the needs of related industries such as packaging and printing for product hot stamping decoration, and improving the appearance grade and market competitiveness of products.

The fluid is incompressible, so it can be used as the transmission medium of the power of the hydraulic stamping machine. Compared with the pneumatic stamping machine, its pressure is higher and more stable. The hydraulic bronzing machine has a wide range of applications in concave and convex bronzing, die cutting, large flat bronzing and bronzing on hard plastics. The hydraulic hot stamping machine supplies the liquid through the hydraulic pump, and the liquid transmits the action to the hydraulic valve and the hydraulic cylinder through the operation command to perform the hot stamping. Due to the huge pressure of the hydraulic bronzing machine, the materials for making the bronzing machine, such as hot stamping, and the workbench all require high-strength steel.

|

Hydraulic embossing stamping Machine //Structure |

||

|

Working table |

High strength Steel plate , size: 520*800mm. |

|

|

Stamping Head drive |

Hydraulic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Max Pressure |

20T |

|

|

Hydraulic embossing stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Hydraulic embossing stamping Machine //Parameter |

||

|

Technical parameters |

HH-TC4050LPT |

HH-TC4060LPT |

| 1. Hot plate area:400 ×500 mm

2. Working table area:520 ×800mm 3. Max printing pressure:20,000 Kg 4. Up and down distance:100mm 5. Heat wattage: 6×800W 6. Foil in feed: Motor Drive 7. Temperature adjustment:0-300oC 。 |

1. Hot plate area:400 × 600 mm

2. Working table area:520 ×800mm 3. Max printing pressure:20,000 Kg 4. Up and down distance:100mm 5. Heat wattage: 6×800W 6. Foil in feed: Motor Drive 7. Temperature adjustment:0-300oC |

|

|

Works supply |

|

|

|

Package list |

Package size: 1.16*1.2*1.9m Gross weight: 1050kg; CBM: 2.6448 |

Package size:0.75*0.55*0.83mm Gross weight: 170kg; CBM: 0.342375Printing |

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Hydraulic embossing stamping machine //Advantage |

||

|

Function |

|

|

Application︰

Hydraulic hot stamping machine is a hot stamping machine that uses hydraulic oil as a power source. Due to the small compression ratio of the liquid, the pressure of the hot stamping machine is strong and stable. It can be used for hot stamping and embossing in paper packaging, gift boxes and wood products. has a wide range of applications. The hydraulic hot stamping machine is supplied with fluid by a hydraulic pump that stores hydraulic oil, and the direction of the fluid is controlled by a hydraulic valve to realize actions such as hot stamping and lifting. The pressure is between 10 tons and 120 tons. Typically, the larger the ironing size, the greater the pressure required.