Model No.︰HH-TC4040LP

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 5147 / pic

Minimum Order︰1 pic

The fluid is incompressible, so it can be used as the transmission medium of the power of the hydraulic stamping machine. Compared with the pneumatic stamping machine, its pressure is higher and more stable. The hydraulic bronzing machine has a wide range of applications in concave and convex bronzing, die cutting, large flat bronzing and bronzing on hard plastics. The hydraulic hot stamping machine supplies the liquid through the hydraulic pump, and the liquid transmits the action to the hydraulic valve and the hydraulic cylinder through the operation command to perform the hot stamping. Due to the huge pressure of the hydraulic bronzing machine, the materials for making the bronzing machine, such as hot stamping, and the workbench all require high-strength steel.

1. Equipment function and principle

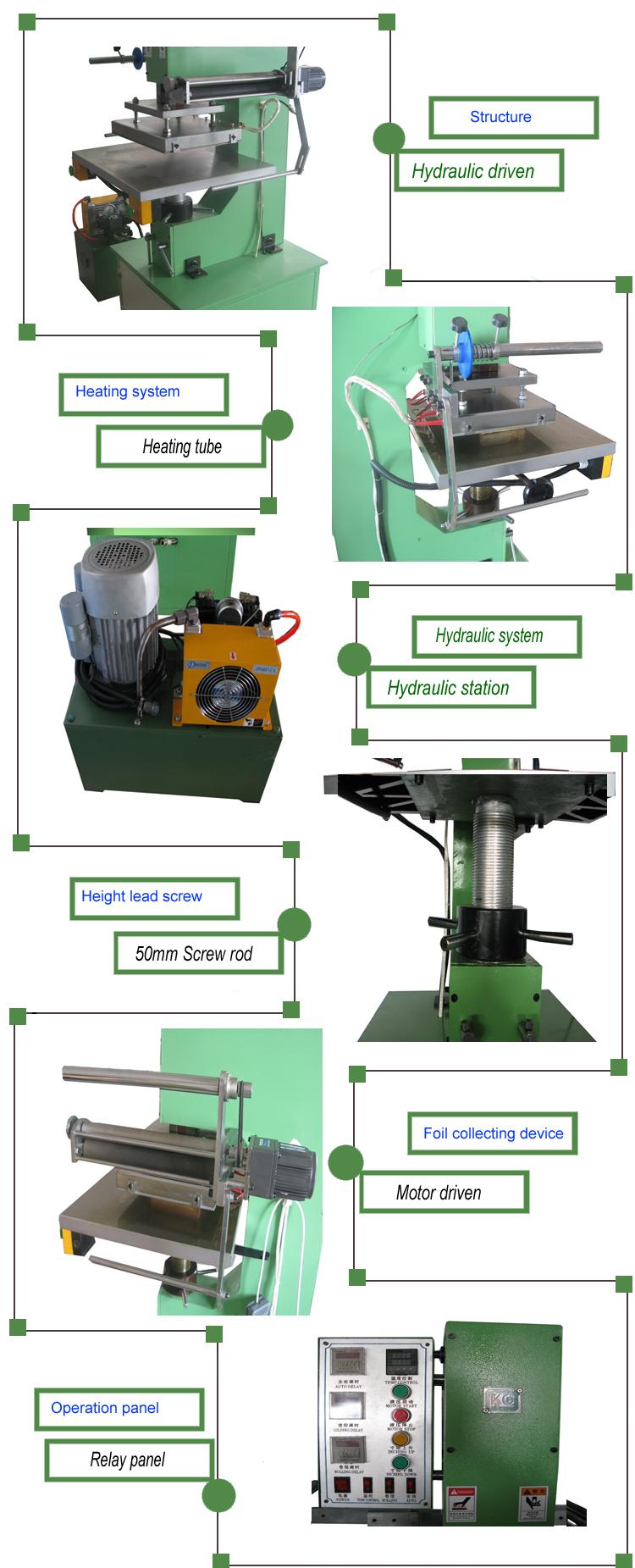

• This hot stamping machine mainly uses hydraulic power to work. The hydraulic system delivers hydraulic oil to the hydraulic cylinder through the oil pump, and the strong pressure generated pushes the piston to move. The piston is connected to the hot stamping plate, so that the hot stamping plate can be pressed down with stable pressure. At the same time, the hot stamping plate is heated to a suitable temperature. When the wooden gift box is placed on the workbench and the hot stamping plate descends to contact the surface of the gift box, under the combined action of pressure and temperature, the metal layer on the hot stamping foil will be transferred to the wooden surface, completing the hot stamping process.

2. Advantages of hydraulic system

• Provide stable pressure: The hydraulic drive can provide very stable and large pressure, which is important for hot stamping on the surface of relatively hard materials such as wood. Stable pressure can ensure the integrity and clarity of the hot stamping pattern, make the gold foil fit closely with the wooden gift box, and ensure uniform hot stamping effect.

• Flexible pressure adjustment: The pressure of the hydraulic system can be flexibly adjusted according to factors such as the material (such as cork or hardwood) of the wooden gift box, thickness, and complexity of the hot stamping pattern. For example, for wooden boxes with a softer texture, the pressure can be appropriately reduced to avoid crushing the box; for the need for hot stamping with fine patterns, the pressure can be appropriately increased to ensure that the pattern is fully transferred.

3. Hot stamping quality assurance

• Accurate positioning: The equipment is usually equipped with a high-precision positioning device that can accurately position the hot stamping pattern on the plane of the wooden gift box. This is essential to ensure the neatness and beauty of the pattern, especially when performing multi-color hot stamping or hot stamping with complex patterns, which can effectively avoid pattern deviation.

• Accurate temperature control: Due to the particularity of wooden materials, such as easy deformation due to heat, the hot stamping machine has high requirements for temperature control. It can accurately control the temperature of the hot stamping plate to ensure that the gold foil is smoothly transferred without damaging the wooden gift box, and the pattern after hot stamping is bright and lasting.

4. Equipment features

• Wide range of applications: It can handle wooden gift boxes of different sizes and shapes. Whether it is a small jewelry box or a larger gift box, as long as it is a flat hot stamping demand, it can be well met.

• Easy to operate: Generally, there is a simple and easy-to-understand operation panel, and the operator can easily set and adjust the parameters such as pressure, temperature, time, etc. of the hot stamping. Moreover, the maintenance of the equipment is relatively simple, and daily maintenance mainly focuses on the inspection of the hydraulic system and the heating system.

• High safety performance: Considering the characteristics of hydraulic equipment and the high temperature during the hot stamping process, it is usually equipped with safety devices such as emergency stop button and double button operation to ensure the safety of operators and the normal operation of the equipment.

5. Application field

• Gift packaging industry: used for hot stamping of various wooden gift boxes, such as high-end cosmetics gift boxes, wine gift boxes, handicraft gift boxes, etc. Hot stamping can improve the grade and beauty of gift boxes and increase the added value of products.

• Personalized customization field: meet customers' personalized hot stamping needs for wooden gift boxes, such as customizing gift boxes with special patterns (company logos, personal signatures, commemorative patterns, etc.), which are used for business gifts, commemorative gifts, wedding gifts and other occasions.

|

Hydraulic embossing stamping Machine //Structure |

||

|

Working table |

High strength Steel plate , size: 480*600mm. |

|

|

Stamping Head drive |

Hydraulic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Max Pressure |

20T |

|

|

Hydraulic embossing stamping Machine //Parameter |

||

|

Technical parameters |

HH-TC3040LP |

HH-TC4040LP |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

Characteristic

Application︰

Hydraulic hot stamping machine is a hot stamping machine that uses hydraulic oil as a power source. Due to the small compression ratio of the liquid, the pressure of the hot stamping machine is strong and stable. It can be used for hot stamping and embossing in paper packaging, gift boxes and wood products. has a wide range of applications. The hydraulic hot stamping machine is supplied with fluid by a hydraulic pump that stores hydraulic oil, and the direction of the fluid is controlled by a hydraulic valve to realize actions such as hot stamping and lifting. The pressure is between 10 tons and 120 tons. Typically, the larger the ironing size, the greater the pressure required.