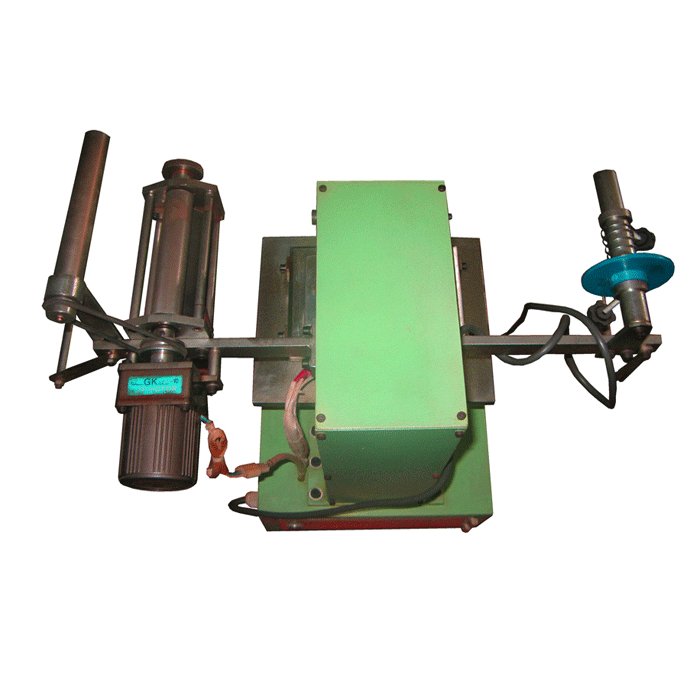

Model No.︰HT-TC1020

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 1411 / pic

Minimum Order︰1 pic

Fishing supplies hot stamping machine

Structure

• Pneumatic system: mainly composed of cylinder, air pipe and control valve. Compressed air is transmitted to the cylinder through the air pipe, and the control valve adjusts the air pressure so that the cylinder generates appropriate pressure to drive the hot stamping component to work.

• Hot stamping component: including hot stamping plate and heating device. There are designed patterns or texts on the hot stamping plate, and the heating device can heat up quickly to ensure that hot stamping materials such as electrochemical aluminum foil can be smoothly transferred to the surface of fishing gear and other items.

• Workbench: Generally a flat tabletop, used to place fishing rods, fishing clothes and other items, usually with a positioning device to ensure the accurate hot stamping position.

Features

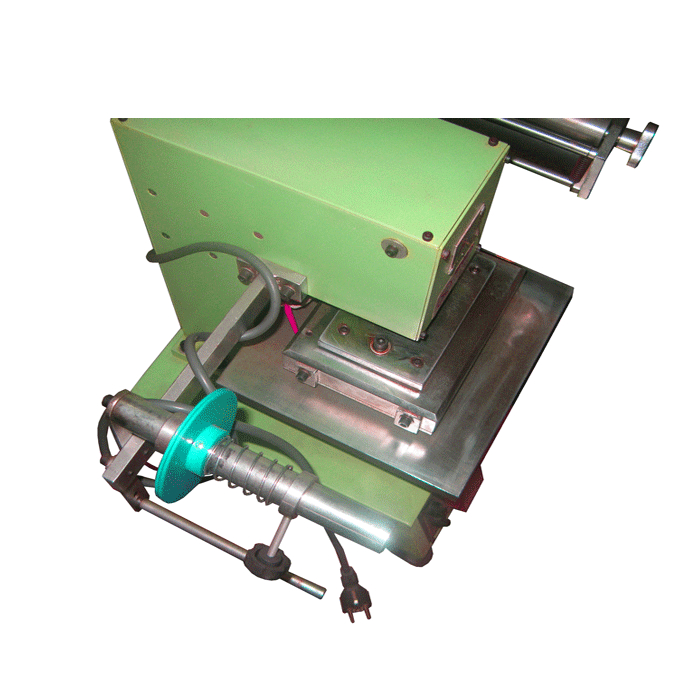

• Flat hot stamping advantage: It can perform high-quality hot stamping on the flat parts of fishing gear, fishing clothes, etc., making the pattern clear and colorful. For example, hot stamping trademark patterns on fishing clothes have exquisite effects.

• Pneumatic operation characteristics: stable air pressure and uniform pressure, avoiding hot stamping defects caused by uneven pressure, especially suitable for products with high surface requirements such as fishing rods.

• Suitable for a variety of materials: Fishing gear made of different materials can be hot-stamped, such as nylon fishing clothes, carbon fiber or fiberglass fishing rods, and plastic bait boxes.

Application

• Brand logo: Hot-stamp brand trademarks and names on fishing rods and fishing clothes to enhance brand recognition and product professionalism.

• Decorative patterns: Hot-stamp some fish-attracting patterns on the surface of lures, or hot-stamp decorative patterns on fishing clothes to increase aesthetics.

|

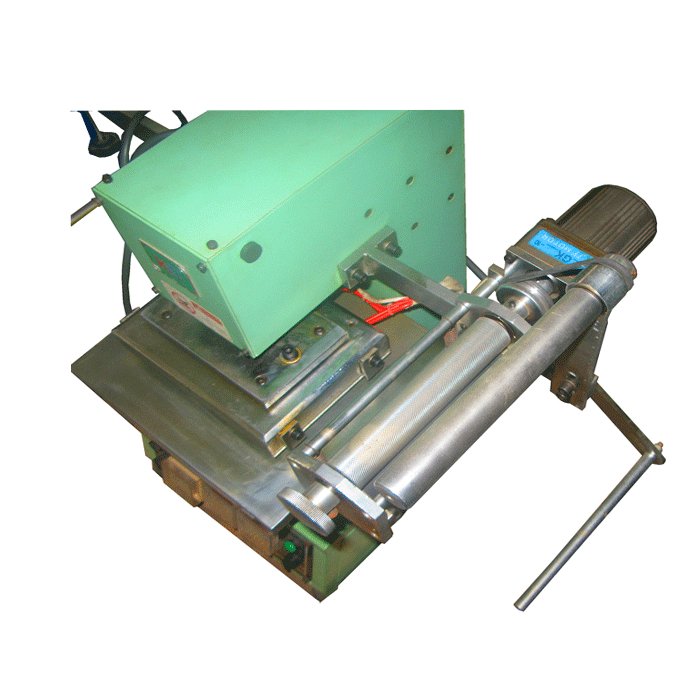

Pneumatic hot stamping Machine//Structure |

||

|

Working table |

High strength Steel plate , size:250*280mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

HT-TC1020 |

HT-TC1520 |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|