Model No.︰H-TC4040LPN

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 6029 / pic

Minimum Order︰1 pic

Pneumatic hot stamping machine for paper factory and printing factory :

Working principle

The pneumatic hot stamping machine uses compressed air to push the hot stamping head down, so that the hot stamping foil and the substrate are closely attached at a certain temperature and pressure. The hot-melt resin layer and adhesive on the hot stamping foil are melted by heat, and the aluminum layer is transferred to the substrate. After cooling and solidification, the hot stamping is completed.

Structural composition

• Automatic entry and exit workbench: It can automatically enter and exit the hot stamping position, reduce the labor intensity of workers, improve safety, and facilitate the placement of workpieces. Some workbenches can also be adjusted forward and backward, left and right, and rotated to meet different hot stamping needs.

• High-strength hot stamping plate: It is usually made of high-strength forged steel and other materials, which can withstand greater pressure, ensure that the hot stamping plate does not deform during the hot stamping process, make the pressure of the hot stamping pattern or text uniform, and improve the hot stamping quality.

• Precision temperature control system: can accurately control the temperature of the hot stamping head to ensure that the resin layer and adhesive of the hot stamping foil melt at the appropriate temperature to achieve a good hot stamping effect. The temperature control range is generally from room temperature to about 280 degrees.

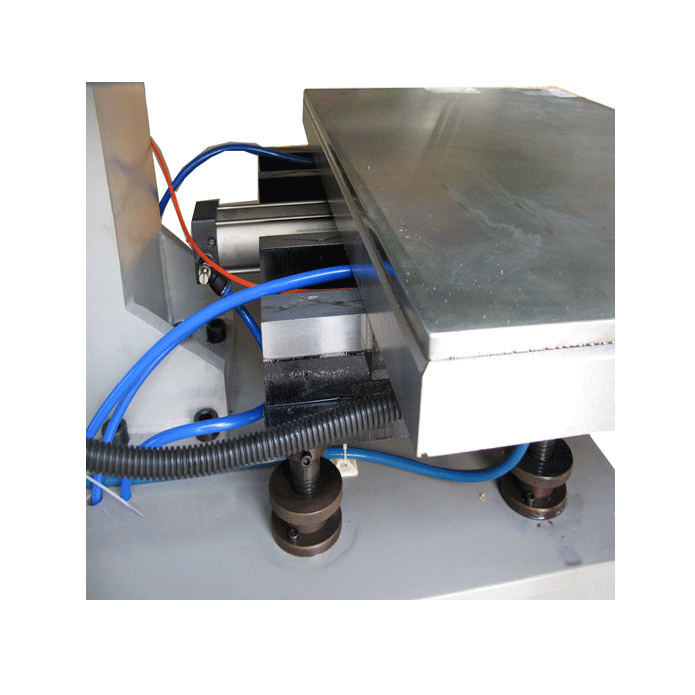

• Pneumatic system: including cylinders, air pipes, air valves and other components to provide power for the hot stamping head to press down. By adjusting the air pressure, the pressure of the hot stamping head can be controlled to adapt to substrates of different materials and thicknesses.

• Control system: mostly using microcomputer program control, can set parameters such as hot stamping pressure, temperature, time, etc., some also have automatic counters built in to achieve semi-automatic and automatic operation, improve production efficiency.

Advantages

• Improve production efficiency: automatic entry and exit of the workbench and automatic paper feeding and collection functions reduce manual operation time and improve production efficiency.

• Improve hot stamping quality: high-strength hot stamping plate and precision temperature control system ensure uniform hot stamping pressure and accurate temperature, making the hot stamping pattern clear, firm and colorful.

• Enhanced safety: Automatic access to the workbench reduces the risk of workers coming into contact with the equipment, and safety devices such as the double switch design further ensure the safety of operators.

Application

In paper products factories, it can be used for hot stamping of paper boxes, cards, wrapping paper, etc., such as hot stamping of logos on gift boxes and patterns on greeting cards; in printing factories, it can be used for hot stamping of book covers, brochures, labels, etc. to enhance the grade and aesthetics of printed products.

|

H-TC4040LPN Pneumatic hot stamping Machine//Structure |

||

|

Working table |

High strength Steel plate , size: 500*650mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Stamping plate size |

400*400mm. |

|

|

H-TC4040LPN Pneumatic hot stamping machine//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

H-TC4040LPN Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC3040LPN Large-pressure hot stamping Machine

|

H-TC4040LPN Large-pressure flat hot stamping Machine

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

H-TC4040LPN Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|

Application︰

There will be huge pressure when the hot plate and the worktable are in contact, which is a potential safety hazard for all hot stamping machines. In order to improve the safety of the hot stamping machine, you can install a safety door, install a safety grating, and use a two-button operation mode. Another important practice is to set the workbench to enter and exit automatically. The workbench enters and exits automatically, which can facilitate the pick-and-place of the product and avoid the safety failure of the operator.

The automatic entry and exit of the workbench is also convenient for the operator to observe the product placement, which is more conducive to product positioning. The complete solution to the safety problem of the semi-automatic plane hot stamping machine is to use a fully automatic hot stamping machine, that is, automatic feeding, automatic hot stamping, and automatic unloading, which completely eliminates the possibility of the operator touching the hot plate and the workbench. However, during the debugging process of the machine, this kind of contact is still unavoidable, and it is necessary to carry out the necessary safety training for the operator.