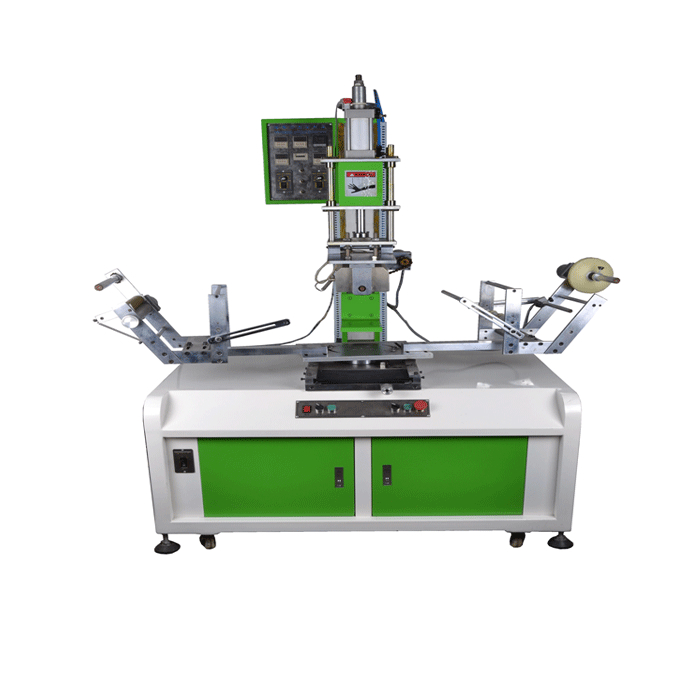

Model No.︰H-100MT

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 5147 / pic

Minimum Order︰1 pic

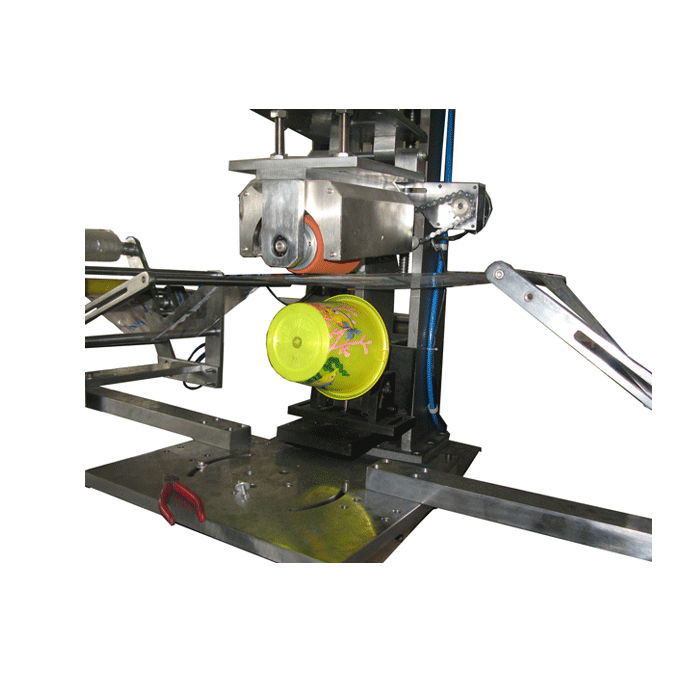

Special cup clamp

• The special cup clamp is an important part of this thermal transfer machine. It can accurately and firmly fix automatic tapered cups and tapered bottles of different sizes and shapes. During the thermal transfer process, it effectively prevents the cups or bottles from shaking, shifting, etc., ensuring that the thermal transfer film can perfectly fit their curved surfaces, laying the foundation for achieving high-quality thermal transfer effects, so that the transfer pattern can be accurately presented in all parts of the cup and bottle body.

Automatic fan-shaped film delivery

• The automatic fan-shaped film delivery function cleverly adapts to the curved surface shape of tapered cups and tapered bottles. By automatically delivering the fan-shaped thermal transfer film, the film can be covered on the surface of the cup and bottle in a more fitting way, ensuring uniform contact between the film and the curved surface during transfer, so that the pattern can be completely and clearly transferred in the part where the taper changes, avoiding transfer defects caused by the mismatch between the film and the object shape.

Photoelectric tracking system

• The photoelectric tracking system plays a key monitoring and calibration role. During the process of conveying and transferring the thermal transfer film, it can monitor the position, status and other information of the thermal transfer film in real time. Once the position of the film is detected to be deviated or abnormal, it can respond quickly and make precise adjustments to ensure that the thermal transfer film is always accurately aligned with the tapered cup and tapered bottle, ensuring the accuracy of the transfer pattern and improving the success rate and quality of the transfer.

Rubber roller heating system

• The rubber roller heating system has an important influence on the effect of thermal transfer. According to the material of the tapered cup and tapered bottle and the characteristics of the thermal transfer film, the rubber roller heating system can accurately adjust the temperature so that the rubber roller can better fit the thermal transfer film with the curved surface of the cup and bottle during the rolling process with the help of the appropriate temperature, so as to facilitate the smooth transfer of the transfer pattern from the film to the surface of the object, and ensure the firmness of the transfer, and improve the durability of the pattern after the transfer.

Key panel operation

• The key panel operation makes the use of the equipment very convenient. Operators can easily set the key parameters of thermal transfer, such as the temperature of the rubber roller heating, the speed of the fan-shaped film automatic conveying, and the sensitivity of the photoelectric tracking system, by simply pressing the buttons on the panel. According to the materials and transfer requirements of different conical cups and conical bottles, the corresponding parameters can be quickly adjusted by simply operating the buttons, which reduces the difficulty of operation and makes the transfer work more efficient.

Applicable scenarios

• This thermal transfer machine is particularly suitable for thermal transfer processing of automatic conical cups (such as coffee cups, tea cups, etc.) and conical bottles (such as perfume bottles, lotion bottles, etc.) in various beverage, cosmetics, daily necessities and other industries. Brand logos, exquisite decorative patterns, etc. can be transferred on these products to effectively enhance the appearance and recognition of the products and meet the production needs of personalized and beautiful products.

|

H-100MT Cone-Cup heat transfer Machine //Structure |

||

|

Working table |

Sector-orbit working table ; |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Automatically film collecting along sector orbit |

|

|

Press adjustment |

Up-down of stamping head |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Stamping roller size |

Width: 200mm, diameter: 125mm. |

|

|

H-100MT Cone-cup heat transfer machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

H-100MT Cone-cup heat transfer Machine //Parameter |

||

|

Technical parameters |

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

H-100MT Cone-cup heat transfer machine //Advantage |

||

|

Function |

|

|

Application︰

Most of the plastic cups have a certain taper. The curved length of the large end and small end of the rotation process is different, and the speed is also different. When used for transposition, the transfer film will wrinkle. In order to avoid wrinkles, there are two main measures: one is to make a fan -shaped transfer film according to the shape of the cup; the other is to use the fertilizer heat transfer controlled by servo, and the thermal transfer film of the conical transfer to transport the film conveyor. The device can be rotated according to the taper of the cup, turning different angles, and transferring the transfer film to the cup. The servo system of the taper thermal transfer machine must ensure that the speed at the contact of the silicone roller and the cup bus is equal, otherwise the phenomenon of wrinkles will still occur.