There are mature solutions for silk screen printing and heat transfer printing on plastic barrels with a diameter of more than 300mm, but hot stamping is indeed more difficult, because the long sides of the rectangular or fan-shaped plastic barrels basically exceed 1M. It is very difficult to maintain very uniform pressure during the contact between the ironing plate and the barrel.

In principle, the hot stamping of plastic barrels is an enlarged version of hot stamping for cup products. Just because the size is too large, the deviation in the rotation process will be enlarged. There are two ways to solve this problem. One is to install the plastic barrel on the arc track and follow the fan track along the ironing plate. The other is to install a servo rotation mechanism on the jig of the hot stamping machine. Each time the hot stamping is only finished. pattern, and then rotate to the next position to stamp the next pattern. It's just that the bronzing pattern is the same. If you want to complete the hot stamping on the entire plastic barrel, you still need to use the principle of a silk screen printing machine.

Generally speaking, hot stamping of plastic barrels is more difficult and costly. Unless users have higher requirements for environmental protection, hot stamping should be the last choice.

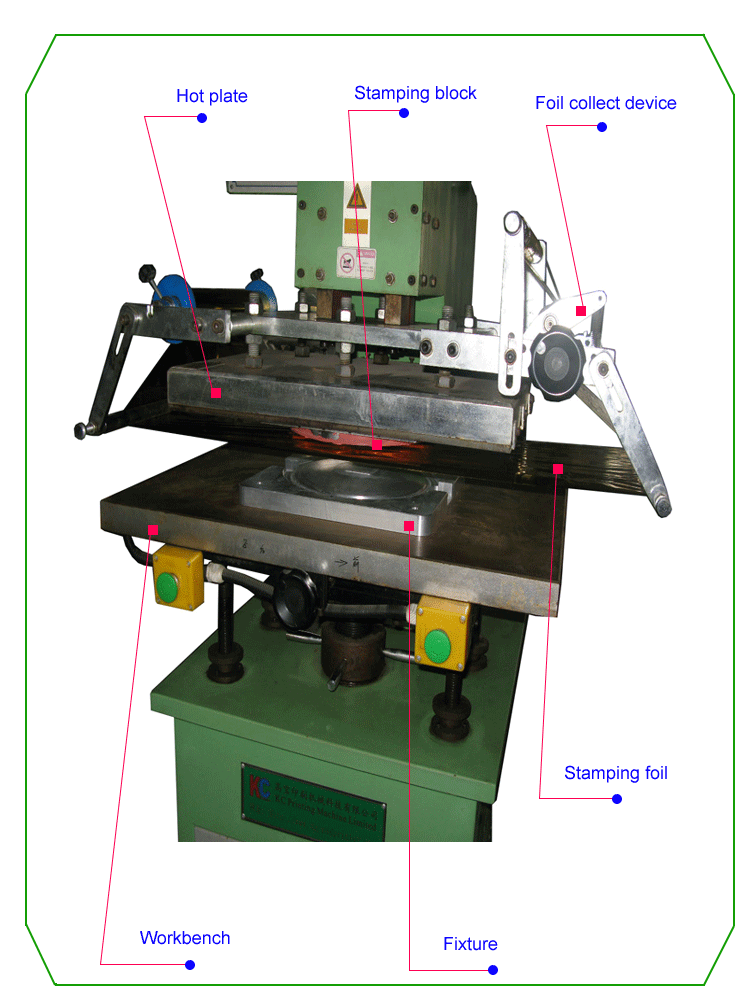

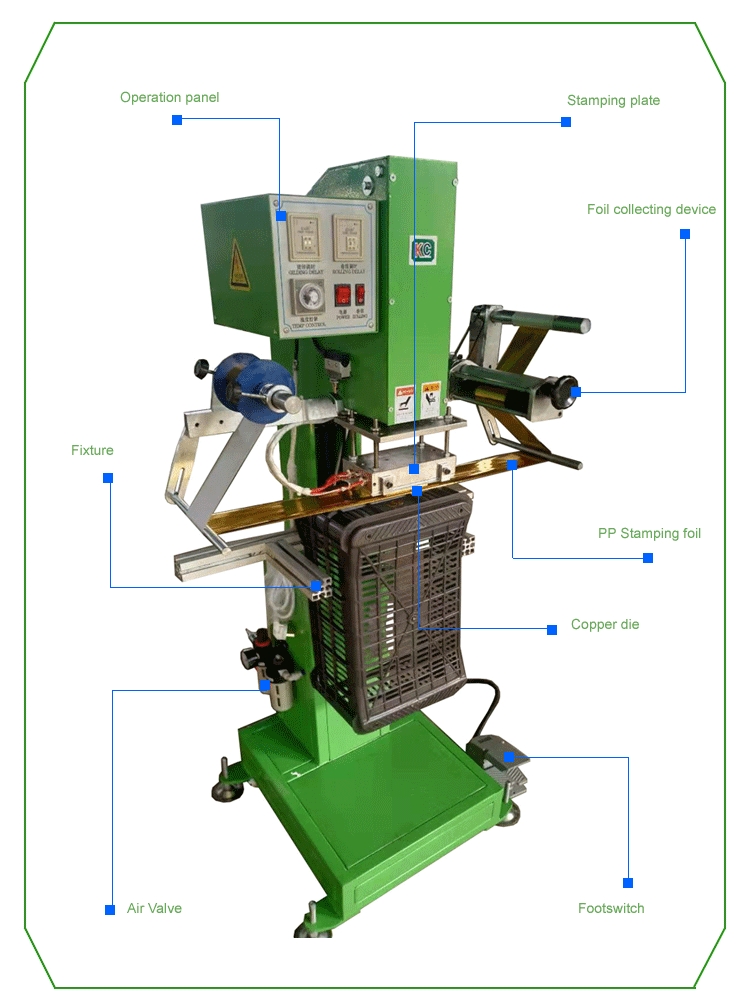

Pneumatic hot stamping machine for crates

The hot stamping of plastic baskets, turnover boxes, trash cans, storage boxes and other products has a huge hollow space, and it is usually necessary to install a cantilever workbench and fixtures for hot stamping. Other hot stamping elements are exactly the same as hot stamping machines. The jig is a positioning device to ensure that the position of the product remains unchanged during the hot stamping process. The pressure it needs to bear is much greater than that of pad printing jigs and silk screen jigs; Type; hot stamping paper is a multi-layer structure formed by coating metal powder on the surface of PET film. Under the action of heat and pressure, the metal coating on the film will transfer to the surface of the product. The choice of hot stamping paper is related to the material of the product, and There are many colors to choose from.

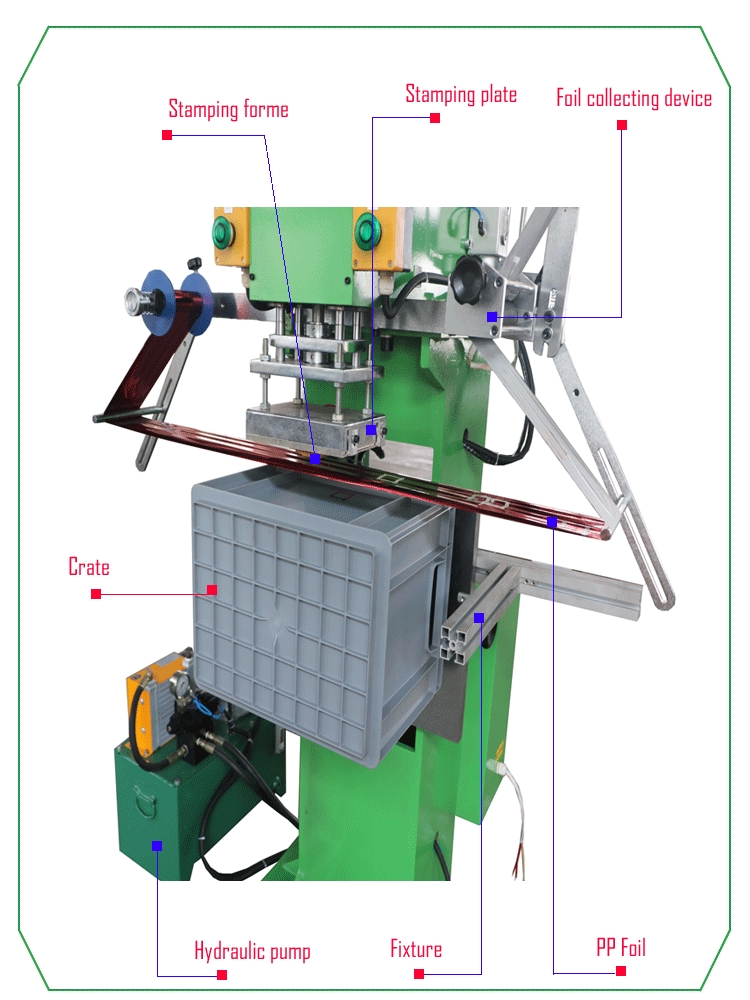

Crate hot foil stamping machine test

Compared with the pneumatic hot stamping machine, the pressure of the hydraulic hot stamping machine is much higher. For some hard plastics or products that use very complicated plastic injection molding, the hydraulic hot stamping machine can obtain much greater adhesion. You may encounter some very difficult For hot stamping plastic products, no matter how the temperature is raised, no matter how the hot stamping paper is replaced, the hot stamping paper will fall off. This may be caused by insufficient pressure of the hot stamping machine. You might as well use a hydraulic hot stamping machine to test the effect. The hot stamping of plastic baskets, turnover boxes, trash cans, storage boxes and other products has a huge hollow space, and it is usually necessary to install a cantilever workbench and fixtures for hot stamping. Other hot stamping elements are exactly the same as hot stamping machines. The jig is a positioning device to ensure that the position of the product remains unchanged during the hot stamping process. The pressure it needs to bear is much greater than that of pad printing jigs and silk screen jigs; Type; hot stamping paper is a multi-layer structure formed by coating metal powder on the surface of PET film. Under the action of heat and pressure, the metal coating on the film will transfer to the surface of the product. The choice of hot stamping paper is related to the material of the product, and There are many colors to choose from.

Stamping on Gift case with hydraulic hot stamping machine

The hydraulic hot stamping machine is a hot stamping machine that uses fluid as the power transmission medium. Because the fluid has a small compression space, it can transmit the original pressure to the actuator almost unchanged. Therefore, the pressure loss is much smaller than that of the pneumatic hot stamping machine. The pressure obtained on the scale of the section is greater, so the hydraulic hot stamping machine is widely used in the hot stamping of large-area products.

The hot stamping elements of the hydraulic hot stamping machine are the same as those of the pneumatic hot stamping machine, which need hot plate, fixture and hot stamping paper. The pressure of the hydraulic hot stamping machine is huge, and it has obvious advantages in some products that are difficult to hot stamp, such as hard plastic and concave-convex hot stamping.

Generally speaking, the hydraulic hot stamping machine is the same as the pneumatic hot stamping machine, except for the paper, it needs to make jigs, and the jigs that need to be made by the hydraulic hot stamping machine have to bear greater pressure.

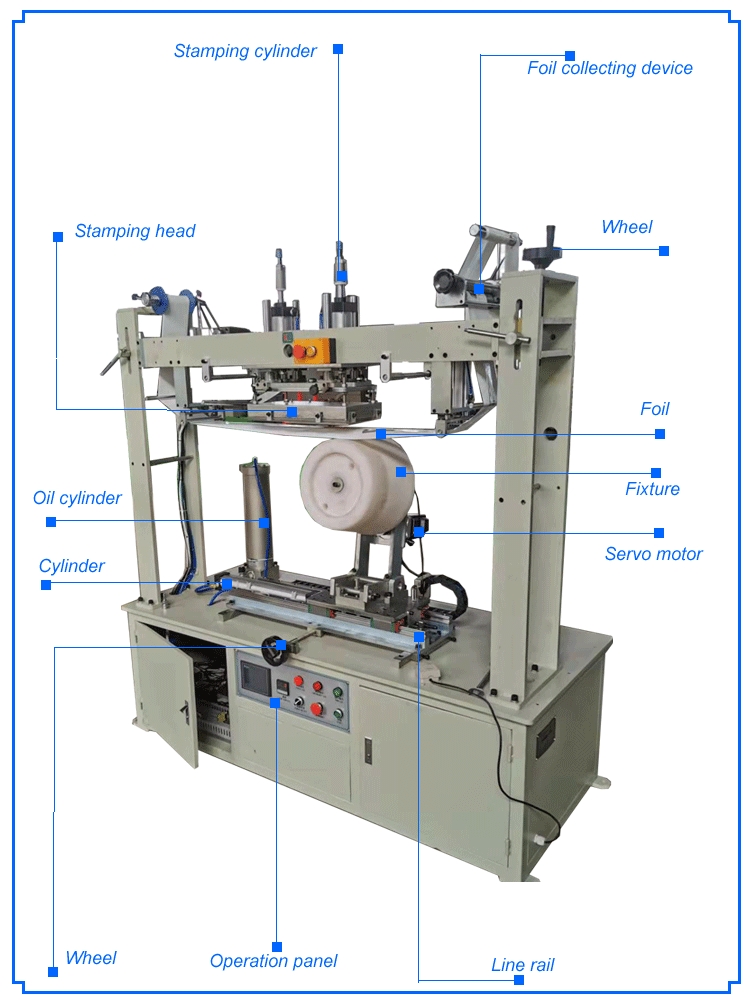

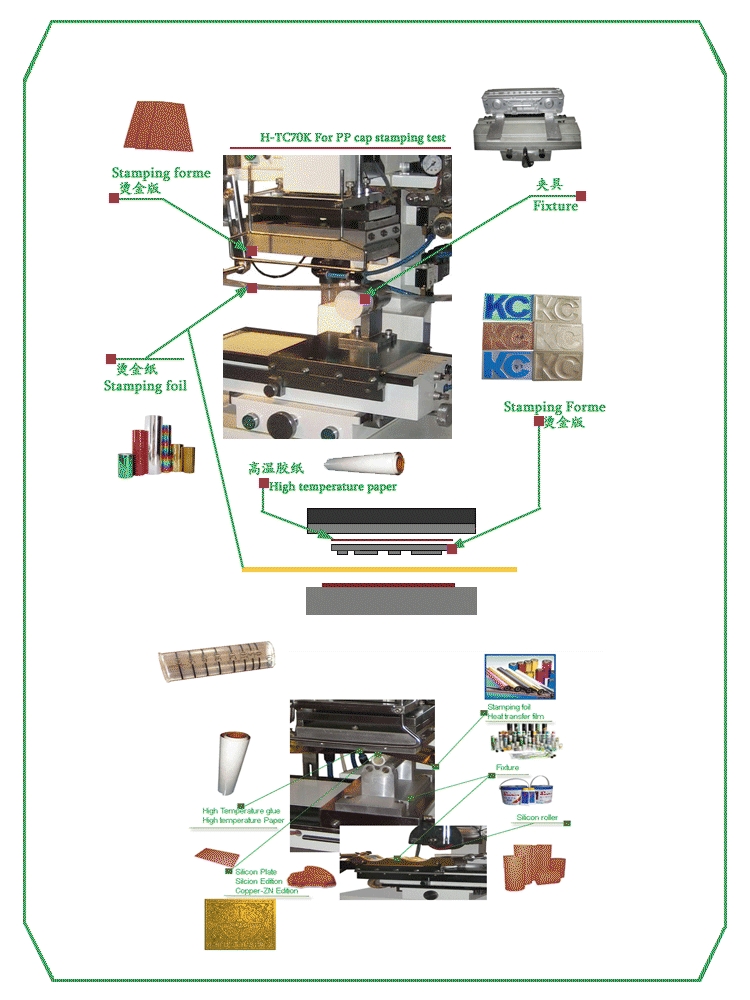

Bottle cap stamped with Cylinder hot foil stamping machine

Curved surface hot stamping machine refers to the equipment for hot stamping on the surface of a cylinder or an approximate cylinder. Its principle is similar to that of a curved surface screen printing machine. First, the product is fixed on a rotatable fixture and fixed on the workbench. When the ironing plate is pressed down and When the product is in contact, the product will rotate along the ironing plate, so that the template on the ironing plate will emboss the hot stamping paper in the circumferential direction of the product.

Surface hot stamping machines are now beginning to be automated on a large scale, with significant improvements in speed and quality.

The most important difference between the curved surface stamping machine and the plane hot stamping machine is that the curved surface stamping machine is equipped with a rotatable fixture, and at the same time, the hot plate should keep in continuous contact with the product for a certain period of time.

The products involved in curved surface stamping machines often require a very large production volume, such as bottle caps, bottles, cosmetic boxes, etc. In order to meet the needs of more users, the structure of curved surface stamping machines is constantly upgraded, such as flat turntable hot stamping machines, vertical turntables Hot stamping machine, automatic feeding hot stamping machine, some hot stamping machines are single-station, some are multi-station. It has become the mainstream direction of the market to customize hot stamping machines with different structures according to the needs of customers.

Hot stamping for clock disc

The dials of some suspended timepieces are cast in resin, and to achieve an eye-catching visual effect, hot stamping on the dials is a very common process. Fixtures: Planar watch dial fixtures are easy to make, but some spherical and more complex watch dials may be completed with superb processing technology to ensure that the product can withstand huge pressure without being damaged. The clock dial can withstand a certain amount of pressure, but another way to relieve its pressure is to use a silicone rubber stamping template. Another obvious advantage of the silicone rubber template is that it can make a model that fits the shape of the product to achieve the pressure of the stamping process. Balanced, the silicone rubber mold is usually cast on the aluminum plate with silicone rubber. Hot stamping paper: The hot stamping paper on the clock dial is generally made of pure gold, silver, blue, red and other bright metal foils.